The Purpose and Function of Car Bumper Molding

The Car Bumper Molding plays a vital role in the overall structure and functionality of modern vehicles. While it might appear to be just a decorative or minor component, it actually serves multiple essential purposes that contribute to both vehicle performance and protection. Its existence is a result of practical engineering, aesthetic considerations, and safety standards that have evolved over decades of automotive design.

- Protection from Impact: One of the main reasons for the inclusion of Car Bumper Molding is to absorb minor impacts and protect the bumper and surrounding parts.

- Aesthetic Enhancement: It improves the overall appearance of the vehicle, giving it a refined and finished look.

- Aerodynamic Contribution: In some designs, it assists with the vehicle's aerodynamics by streamlining airflow around the bumper area.

The Car Bumper Molding acts as a protective barrier between the vehicle's main body and external factors such as minor collisions, debris, or environmental exposure. It can absorb small shocks that might otherwise cause damage to the bumper surface. This not only prevents costly repairs but also helps maintain the car's visual appeal. Moreover, the molding complements the lines and curves of the car, offering a smooth transition between body panels.

Beyond protection and style, the Car Bumper Molding also plays a subtle but important role in improving airflow. By reducing turbulence around the edges of the bumper, it contributes to the vehicle's fuel efficiency and overall stability at higher speeds. For automakers, this combination of form and function justifies the molding's continued use in car design.

The Materials and Design Behind Car Bumper Molding

The material composition of Car Bumper Molding is carefully chosen to balance flexibility, durability, and aesthetic compatibility. Automotive engineers consider how the molding will perform under different temperatures, impacts, and environmental conditions before selecting the appropriate material.

- Common Materials: Many Car Bumper Molding products are made from materials such as rubber, ABS plastic, PVC, or polyurethane. These materials provide both flexibility and resistance to damage.

- Color and Finish Options: Molding can be painted, chrome-plated, or left in its natural black finish, depending on the car's design.

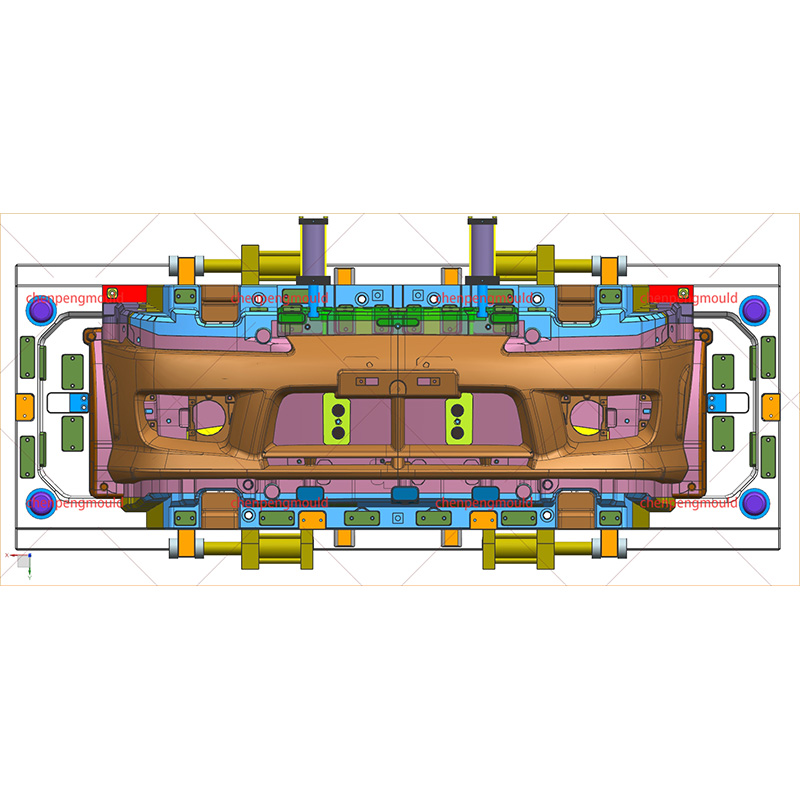

- Attachment Methods: Molding can be attached using clips, adhesives, or integrated into the bumper during manufacturing.

Rubber and flexible plastics are often used because they can absorb small impacts and resist cracking. ABS plastic, in particular, is favored for its light weight and ability to hold paint well, allowing it to match the car's color scheme perfectly. Chrome or metallic finishes, meanwhile, are selected to add a visual accent to luxury or performance models.

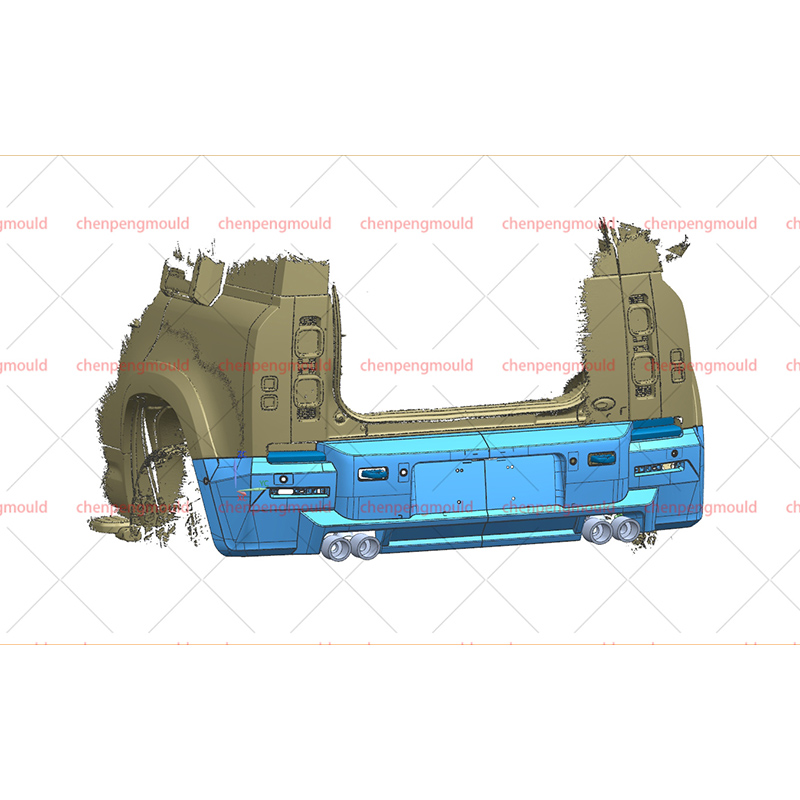

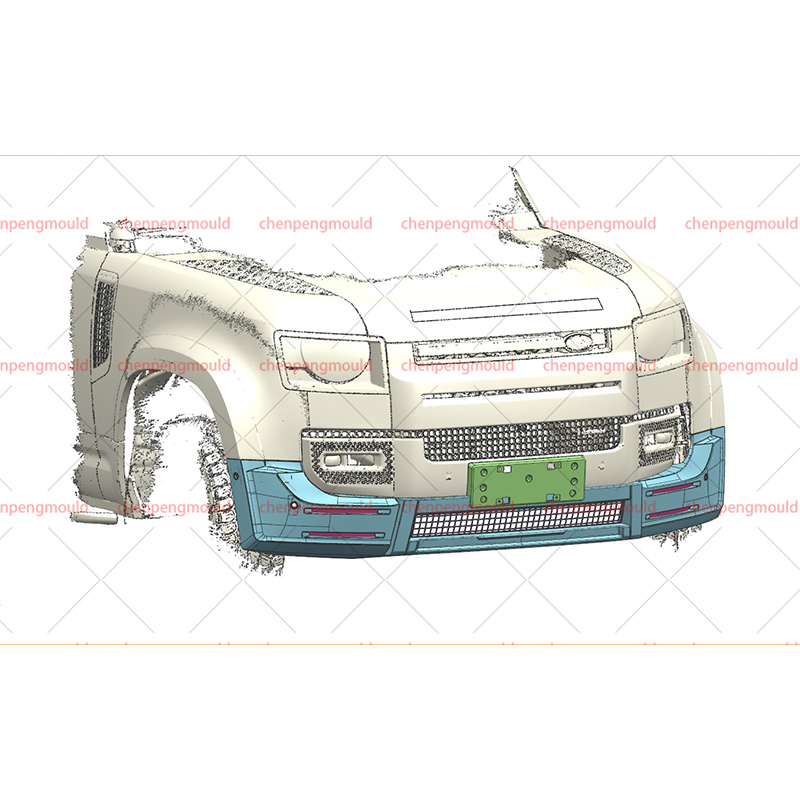

The Car Bumper Molding is designed with precision to fit seamlessly along the bumper's surface. Manufacturers use molds and computer-aided design (CAD) systems to ensure a match with each vehicle model. The attachment method also varies based on design intent—adhesive-backed moldings are easier to replace, while integrated moldings offer a cleaner, factory-installed look.

Each material and attachment method contributes to the molding's longevity and effectiveness. The result is a component that can endure exposure to sunlight, rain, and road debris while maintaining its structure and appearance.

The Maintenance and Importance of Car Bumper Molding

Proper maintenance of the Car Bumper Molding ensures that it continues to serve its protective and decorative functions throughout the vehicle's lifespan. Although it is built to last, periodic cleaning and inspection can help prevent wear and tear.

- Regular Cleaning: Dirt, grime, and road salt can accumulate, potentially affecting the molding's finish or adhesion.

- Inspection for Damage: Checking for cracks or detachment ensures early detection of any issues.

- Replacement Considerations: Over time, if the Car Bumper Molding becomes worn or faded, replacement is an easy and cost-effective way to refresh the car's appearance.

Maintaining the molding not only preserves the vehicle's aesthetic value but also helps sustain the protective role it plays. If debris or moisture gets trapped underneath a loose molding, it could eventually affect the underlying bumper material. Regular cleaning with mild soap and water helps prevent buildup, while using protective coatings can extend its shine and resistance to UV damage.

Replacing the Car Bumper Molding is relatively simple and inexpensive, which makes it an appealing maintenance step for car owners who want to keep their vehicles looking well-maintained. Modern moldings are often designed for easy removal and reinstallation, reducing labor costs and effort.

Moreover, the presence of Car Bumper Molding contributes to the resale value of a car. A well-maintained molding reflects the owner's attention to detail and can enhance the overall impression a potential buyer has of the vehicle. Thus, even though it may seem like a small part, it plays a broader role in both practical and economic terms.

+86-18357617666

+86-18357617666