Front bumper molding is an essential component of modern vehicles, providing both functional and aesthetic benefits. It enhances the vehicle’s appearance while offering protection against minor impacts and scratches.

Advantages of Front Bumper Molding

1. Impact Absorption and Protection

One of the primary advantages of front bumper molding is its ability to absorb minor impacts. It provides a protective barrier for the vehicle’s front end, helping to prevent damage to the main bumper, headlights, and other components. This feature is especially valuable during low-speed collisions or parking maneuvers, where the risk of scratches and dents is higher.

2. Enhanced Vehicle Appearance

Front bumper molding contributes to the overall aesthetics of a vehicle. It offers a clean, streamlined look that complements the car’s design. Available in different finishes, including painted, chrome, or matte, bumper molding can enhance a vehicle’s style and give it a more polished appearance.

3. Scratch and Wear Resistance

Front bumper molding acts as a shield against everyday wear and tear. It protects the vehicle’s surface from scratches caused by debris, minor impacts, or contact with other objects. By preserving the original paint and surface, bumper molding helps maintain the vehicle’s resale value.

4. Lightweight and Durable

Modern bumper moldings are made from high-quality materials such as ABS plastic, polyurethane, or polycarbonate. These materials are lightweight yet durable, providing long-lasting protection without adding significant weight to the vehicle. The combination of strength and lightness also contributes to fuel efficiency and handling.

5. Easy Installation and Replacement

Front bumper moldings are designed for easy installation. Many moldings come with pre-fitted clips or adhesive backing, making it convenient for manufacturers and repair professionals to fit them onto vehicles. In case of damage, replacing the molding is simpler and more cost-effective than repairing the main bumper.

6. Versatility Across Vehicle Models

Bumper moldings are available in a variety of designs, sizes, and finishes to suit different vehicle models. This versatility allows manufacturers to create a consistent look across a car series while providing functional protection. Customizable options also allow car owners to enhance their vehicle’s style according to personal preferences.

Working Principles of Front Bumper Molding

Front bumper molding works by combining design, material properties, and installation techniques to provide protection and enhance aesthetics. Its operation can be understood in several key aspects:

1. Material Selection

The performance of bumper molding starts with the choice of materials. ABS plastic is widely used due to its impact resistance, durability, and ease of molding. Polyurethane and polycarbonate are also popular, offering flexibility and resilience. The selected material determines the molding’s ability to absorb shocks, resist scratches, and maintain its shape over time.

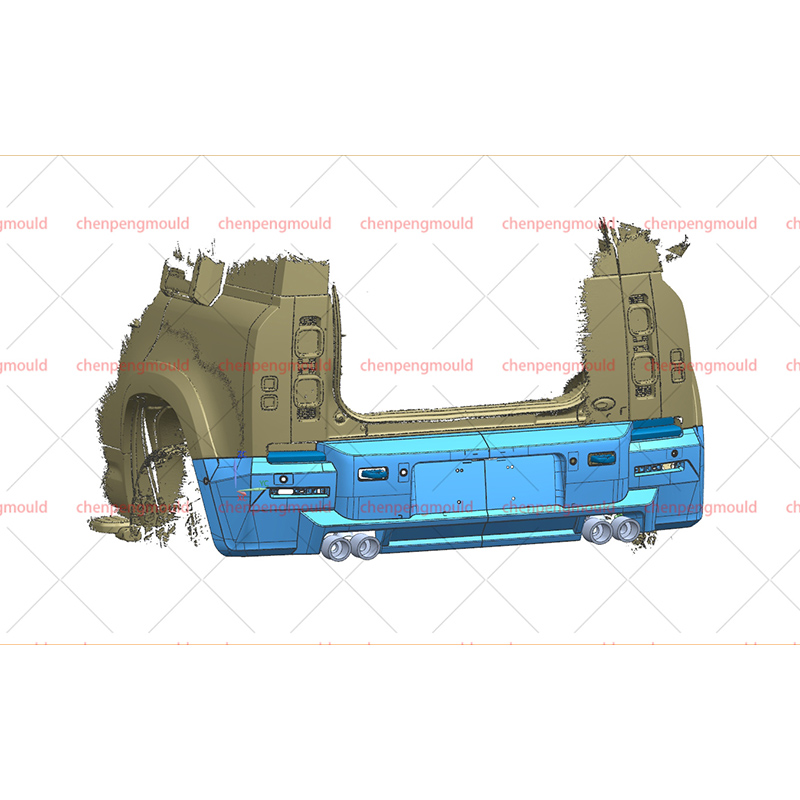

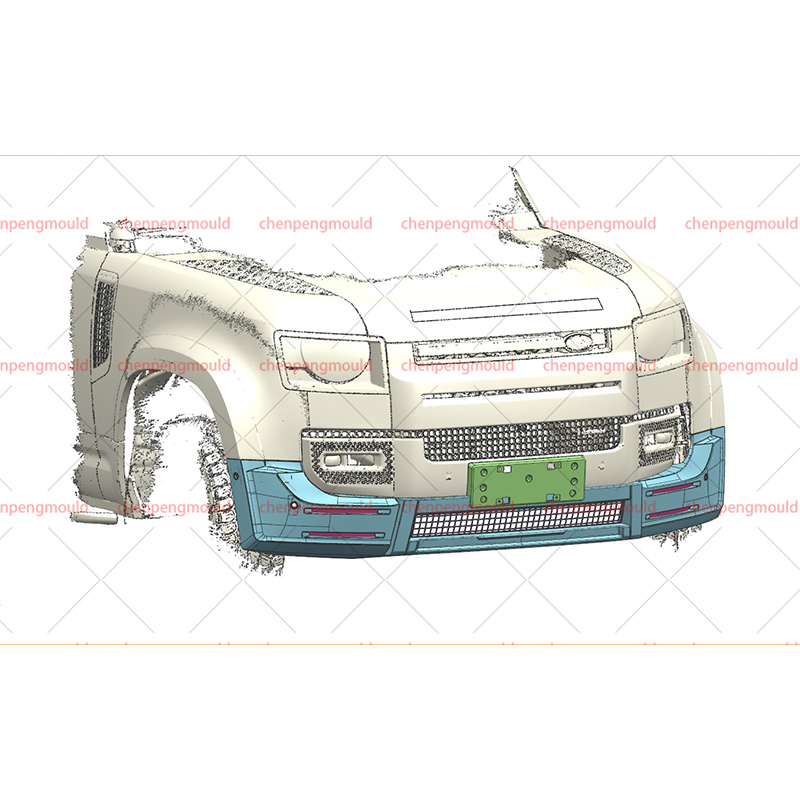

2. Design and Shaping

Bumper moldings are designed to match the contours of the vehicle’s front end. Using precise measurements and CAD technology, manufacturers create molds that ensure a fit. The shape is engineered to provide coverage, protect key areas, and complement the car’s aesthetic lines.

3. Mounting and Fixing

The molding is attached to the vehicle using clips, screws, or adhesive backing. The installation method ensures the molding is securely fixed while allowing slight flexibility to absorb minor impacts. Proper alignment during mounting is essential to achieve a seamless appearance and protection.

4. Impact Absorption

The primary functional principle of bumper molding is impact absorption. When the vehicle experiences minor collisions, the molding deforms slightly to dissipate energy. This reduces the force transmitted to the main bumper and other front-end components, preventing damage and maintaining structural integrity.

5. Surface Protection

In addition to absorbing impact, bumper molding protects the vehicle’s surface from scratches, dust, and debris. The smooth and durable finish of the molding reduces friction and prevents minor abrasions, preserving the vehicle’s paint and appearance.

The working principles of front bumper molding—material selection, precise design, secure mounting, impact absorption, and surface protection—demonstrate how this component enhances both safety and aesthetics. By incorporating high-quality bumper moldings, manufacturers and car owners can maintain vehicle integrity, improve appearance, and ensure long-lasting performance.

Front bumper molding is a practical and stylish solution that combines functionality and design, making it an essential feature in modern automotive engineering.

+86-18357617666

+86-18357617666