The development and manufacturing of auto parts molds involve a wide range of design considerations aimed at producing precise, durable, and efficient components for the automotive industry. From the perspective of a manufacturer, the success of a molding project relies not just on tooling and materials, but also on the thoughtful application of practical design solutions that address the specific requirements of vehicle parts.

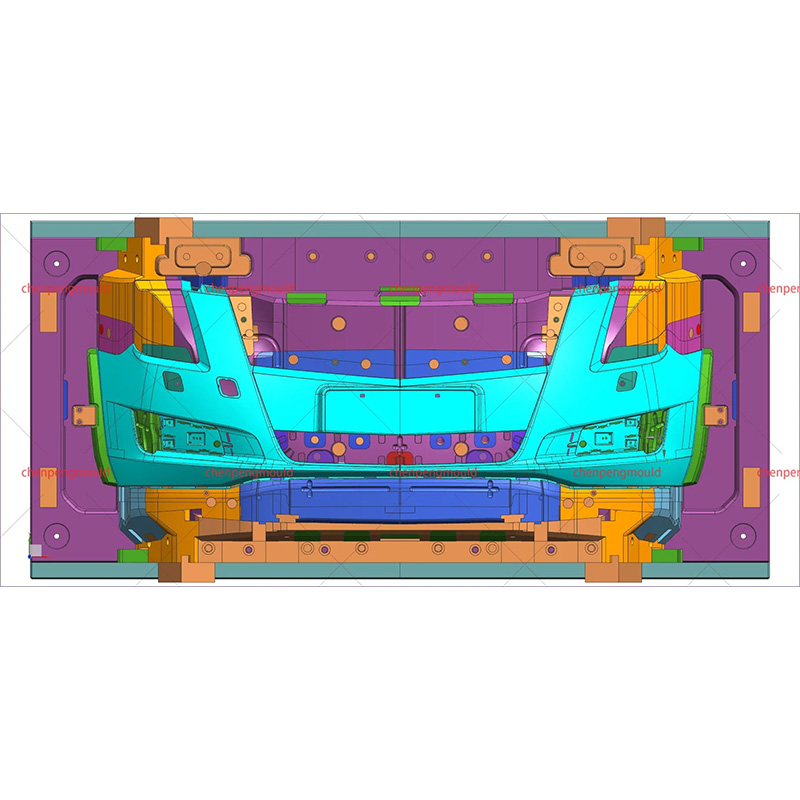

One of the foundational factors in creating an effective auto parts mold is the geometry of the component itself. Automotive parts often have complex shapes that must meet strict dimensional tolerances and integrate seamlessly into larger assemblies. Whether it's a dashboard bracket, grille, or housing for sensors, each part requires mold cavities that mirror its intricate design.

To address this, engineers use 3D modeling software to simulate how molten materials will flow through the auto parts mold, helping identify areas where defects might occur—such as air traps, weld lines, or sink marks. Geometry also affects how the part is released from the mold, making proper draft angles and surface finishes crucial to the success of each cycle.

Different components in a vehicle require different types of plastics or polymers based on heat resistance, impact strength, or flexibility. The auto parts mold must be tailored accordingly to accommodate the chosen material. For example, high-gloss interior trim pieces may use ABS, while under-hood applications may require reinforced nylon.

As a result, the mold must be able to withstand specific processing temperatures and pressures while ensuring consistent flow and fill. The internal surface of the auto parts mold is often treated or coated to ensure it resists wear when abrasive materials or glass-filled polymers are used.

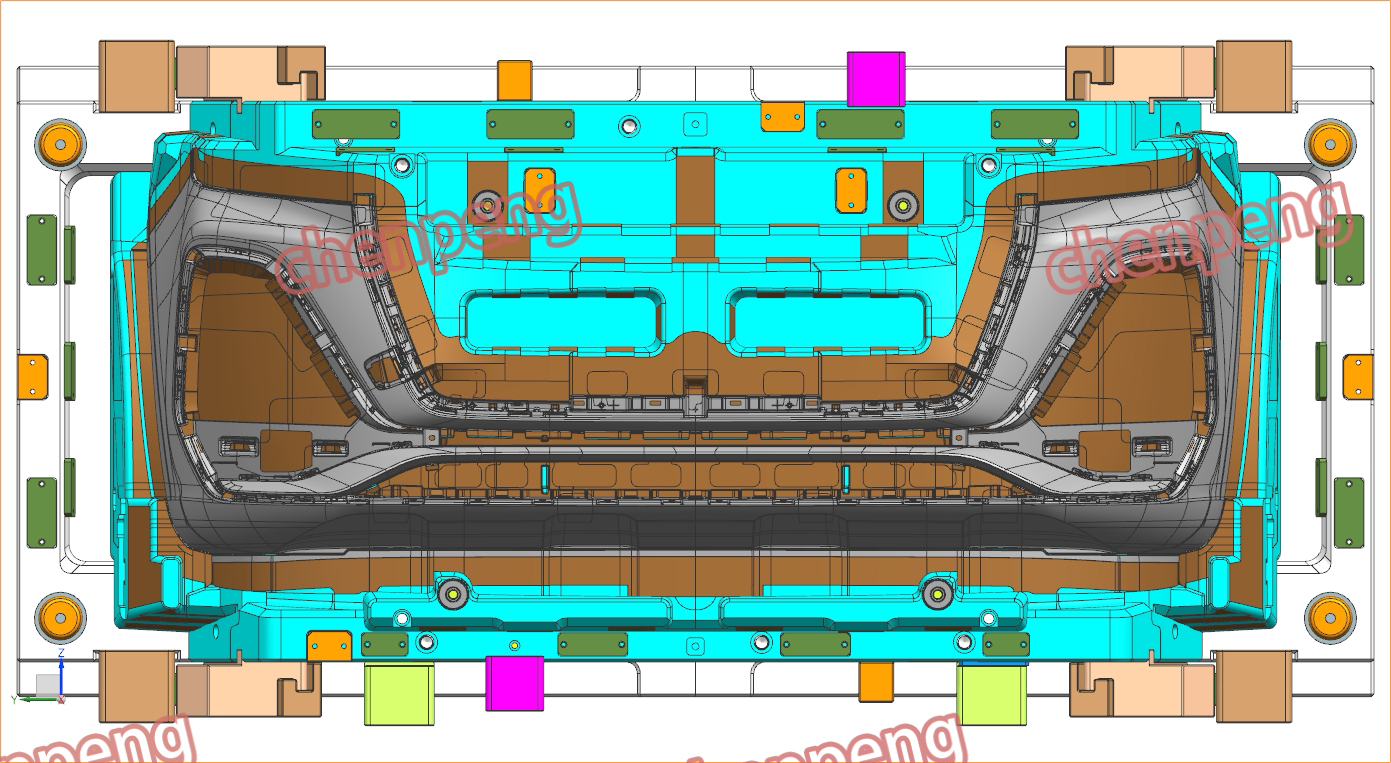

Efficient temperature control is a key design consideration for any auto parts mold. To maintain dimensional accuracy and reduce cycle time, the mold must cool uniformly. If some regions cool faster than others, it can warping or internal stresses in the finished component.

Engineers design integrated cooling channels within the auto parts mold that allow temperature-regulating fluids—typically water or oil—to flow through critical areas. Placement, size, and flow rate of these channels are calculated to optimize the thermal behavior of the mold without compromising its structural integrity.

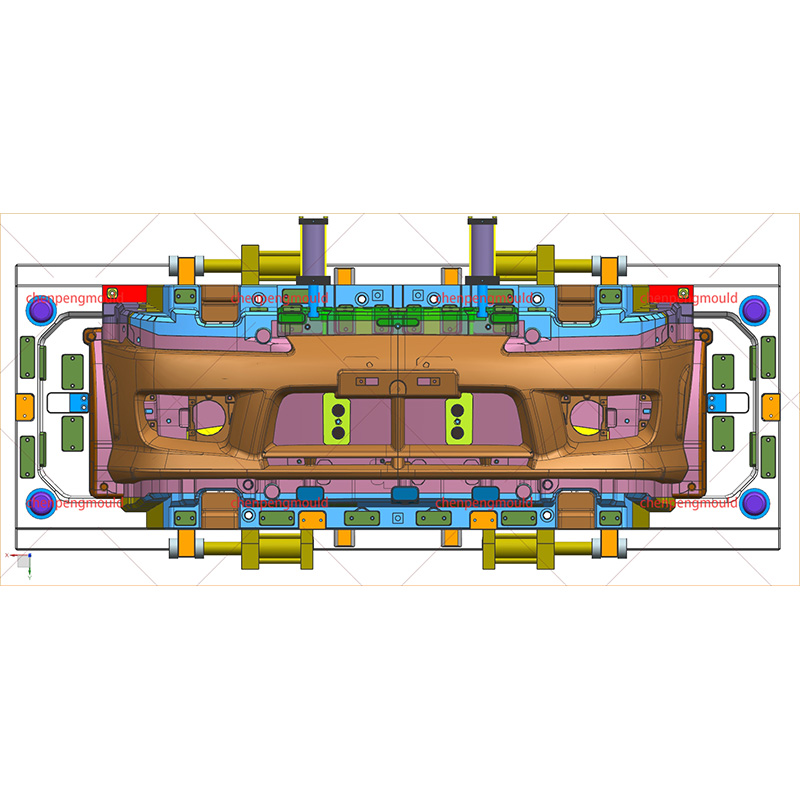

Once a part is molded, it must be removed cleanly without causing deformation or surface defects. This is where ejection systems come into play. The design of the auto parts mold includes ejector pins, lifters, or even air-assist systems depending on the shape and material of the part.

The timing and movement of these systems are synchronized with the opening of the mold, and their placement is carefully planned to avoid visible marks on functional or cosmetic surfaces. For manufacturers, ejection-related damage is essential to maintaining quality and reducing rework.

Air trapped inside a mold cavity can result in incomplete filling or surface blemishes. Therefore, ventilation is another important aspect of auto parts mold design. Small vent grooves are added in non-visible areas to allow gases to escape during the injection process.

If not properly implemented, poor venting can also affect the longevity of the auto parts mold itself, as trapped gases under high pressure may cause burning or corrosion in localized spots. Proper venting ensures both process stability and part integrity.

For high-volume production, multiple parts are often produced simultaneously using a multi-cavity auto parts mold. In cases where different parts of the same assembly are molded together, a family mold design may be used. These approaches increase productivity but require precise balancing of flow channels to ensure all cavities fill evenly.

Manufacturers must also consider mold alignment, pressure distribution, and thermal management when designing multi-cavity auto parts molds, as uneven performance between cavities can result in inconsistent part quality.

+86-18357617666

+86-18357617666