As car manufacturing grew, the aesthetic aspect of vehicles became increasingly important. Automakers began to explore ways to integrate bumpers more smoothly into the car's body. However, the heavy steel bars remained prevalent due to their durability and manufacturing simplicity.

The transition from simple steel bumpers to molded bumpers marked a significant development in automotive design. This shift began in the mid-20th century, driven by several factors:

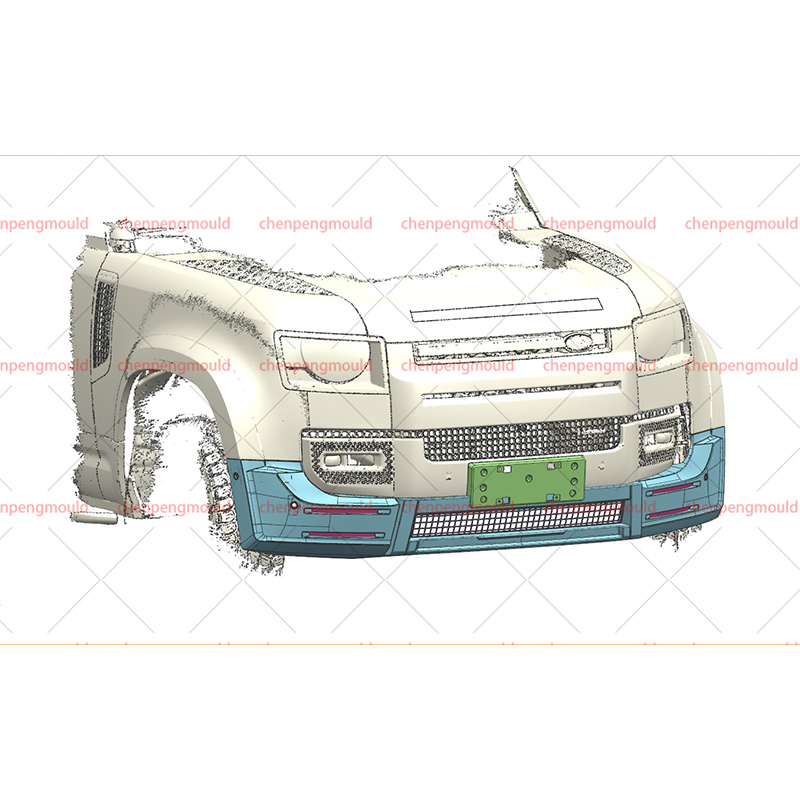

Aesthetic Integration: As car styles evolved, manufacturers sought bumpers that blended seamlessly with the vehicle's body lines. This led to the use of molded plastic components that could be shaped into complex forms, allowing for greater design flexibility.

Weight Reduction: Metal bumpers added considerable weight to vehicles, which affected fuel efficiency and handling. Molded bumpers made from plastics and composites were lighter, contributing to improved vehicle performance.

Safety Enhancements: Advances in safety standards prompted manufacturers to develop bumpers that could absorb impact energy more effectively. Molded bumpers with integrated shock-absorbing materials provided better protection for occupants and pedestrians.

The development of plastics and polymer technologies in the automotive industry played a pivotal role in this transition. Materials such as polypropylene, thermoplastic olefins (TPO), and polyurethanes became common choices for car bumper molding because of their strength, flexibility, and ability to be colored and textured to match vehicle paint.

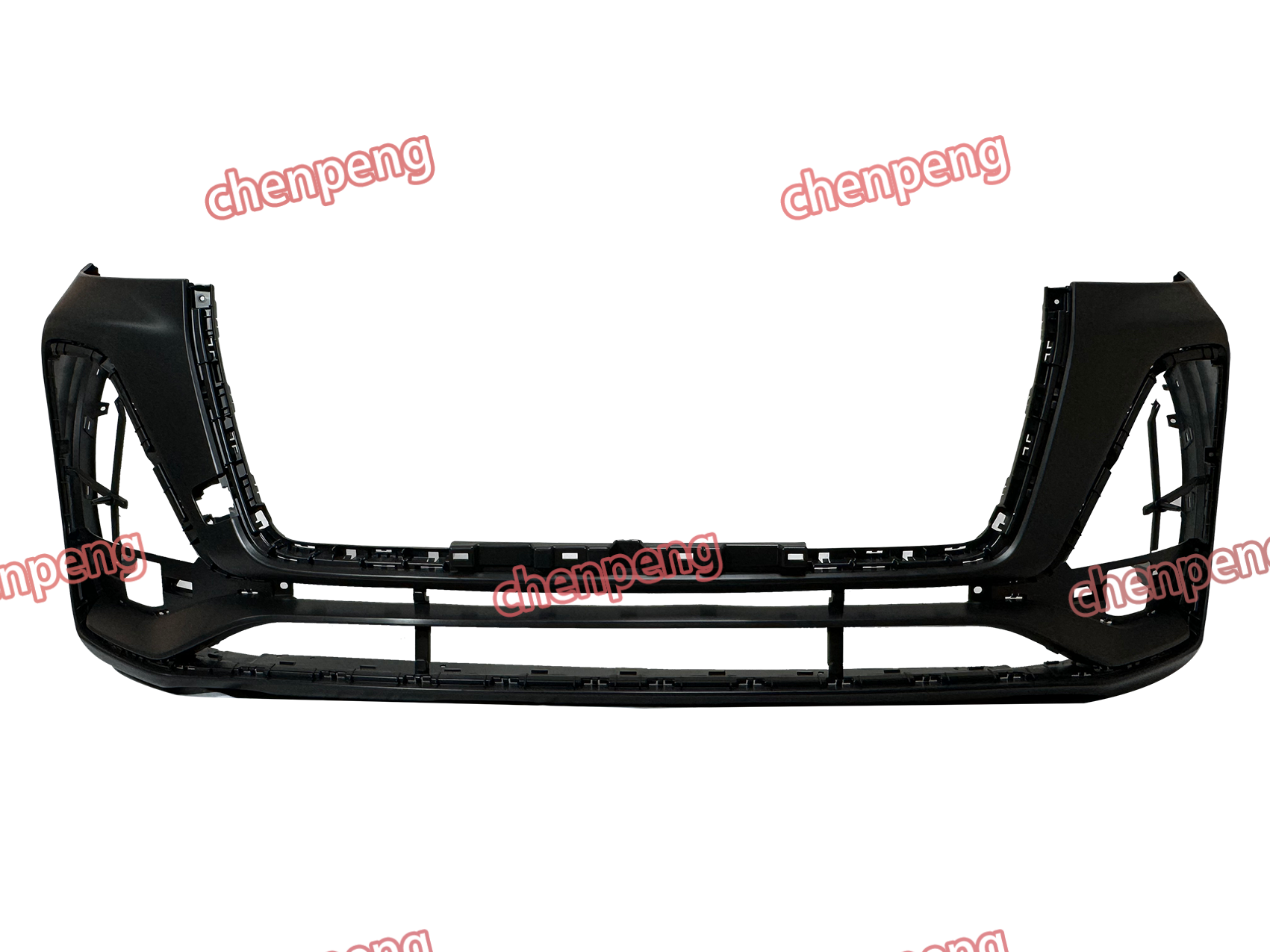

The evolution of manufacturing techniques has been essential to the advancement of car bumper molding. Injection molding and compression molding became the standard processes for producing bumper components due to their efficiency and precision.

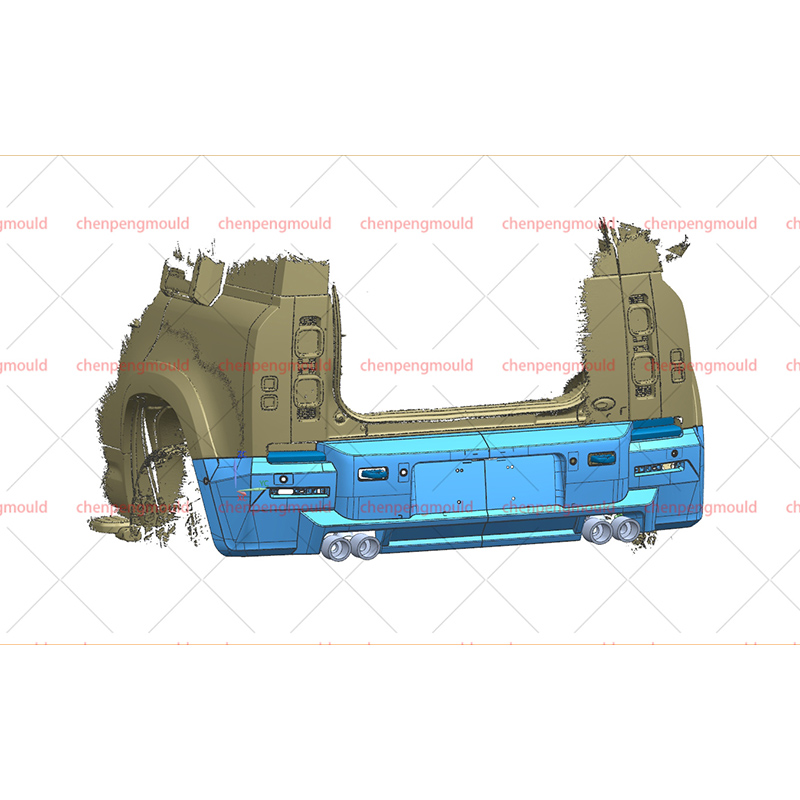

Injection Molding: This process involves injecting molten plastic into a mold cavity under high pressure. It allows for the creation of complex shapes with tight tolerances, smooth finishes, and high repeatability. Injection molding also supports multi-component assembly, which is useful for integrating features like grilles, sensors, and decorative trims directly into the bumper.

Compression Molding: Often used with composite materials, compression molding involves placing a pre-measured amount of material into a heated mold and applying pressure until the material cures. This method is well-suited for producing parts that require high strength and durability, such as impact-resistant bumper cores.

Alongside molding methods, surface finishing techniques such as painting, coating, and texturing have improved the appearance and durability of bumpers. UV-resistant coatings protect plastic bumpers from fading and cracking due to sunlight exposure.

Modern car bumper moldings are no longer standalone protective bars but part of a complex system designed to enhance vehicle safety and functionality. Several technological features have been integrated into bumper molding designs, including:

Impact Absorbers: Energy-absorbing foam or honeycomb structures placed behind the bumper molding to reduce damage during collisions.

Sensors and Electronics: Parking sensors, cameras, and radar units are often embedded within bumper moldings, requiring precise molding and assembly to accommodate these devices.

Aerodynamics: Bumper moldings are designed to improve airflow around the vehicle, reducing drag and improving fuel efficiency.

These advancements underscore the importance of bumper moldings as multifunctional components rather than mere cosmetic additions.

As environmental concerns and regulatory pressures increase, the automotive industry continues to seek sustainable and recyclable materials for bumper molding. Recycled plastics and bio-based polymers are gaining attention for their reduced environmental impact.

Furthermore, the rise of electric vehicles (EVs) and autonomous driving technologies is influencing bumper design. EVs often require optimized aerodynamic bumpers to maximize range, while autonomous vehicles incorporate more sensors, further innovations in molding and integration.

+86-18357617666

+86-18357617666