Front bumper molding refers to the decorative and protective trim components that are attached to or integrated with a vehicle’s front bumper. These moldings are typically made from plastic, rubber, thermoplastic elastomers, or composite materials. Their primary function is to protect the bumper surface from minor impacts, scratches, and abrasion that occur during everyday driving, parking, and low-speed contact. In addition to protection, front bumper moldings also serve a visual purpose by defining styling lines, covering joint gaps, or adding contrast to the bumper surface.

From a manufacturing perspective, these moldings are usually produced through injection molding or extrusion processes, depending on their geometry and material type. After production, they are attached to the bumper using clips, adhesive tapes, or integrated mounting features designed into the bumper itself. The presence of front bumper molding helps manage minor surface damage without requiring replacement of the entire bumper assembly. This can reduce repair costs and simplify maintenance for vehicle owners. In modern vehicle design, bumper moldings also contribute to aerodynamics by smoothing airflow along the front fascia and managing small surface transitions.

What materials are commonly used in front bumper molding production?

Several material types are commonly used in the production of front bumper moldings, each selected based on performance requirements, appearance, and cost considerations. Thermoplastics such as polypropylene (PP), ABS, and PVC are among the widely used materials. These plastics offer a balance between impact resistance, moldability, and cost efficiency. They can be precisely shaped in injection molds and allow for textured or painted surfaces.

Thermoplastic elastomers (TPE and TPV) are also used in applications where flexibility and soft-touch characteristics are required. These materials can absorb minor impacts without cracking and are often selected for moldings that wrap around curved bumper edges. Rubber-based materials may be used in specific protective inserts, although they are less common in modern mass production due to weight and durability limitations.

In some higher-end applications, chrome-plated plastic and painted molding components are used to match vehicle trim or emphasize design features. These materials require additional surface treatment processes such as electroplating, vacuum metallization, or multilayer painting. Each added process increases production complexity and quality control requirements. The choice of material therefore depends on the expected level of impact exposure, environmental conditions, styling goals, and vehicle positioning within the market.

How does the front bumper molding manufacturing process work?

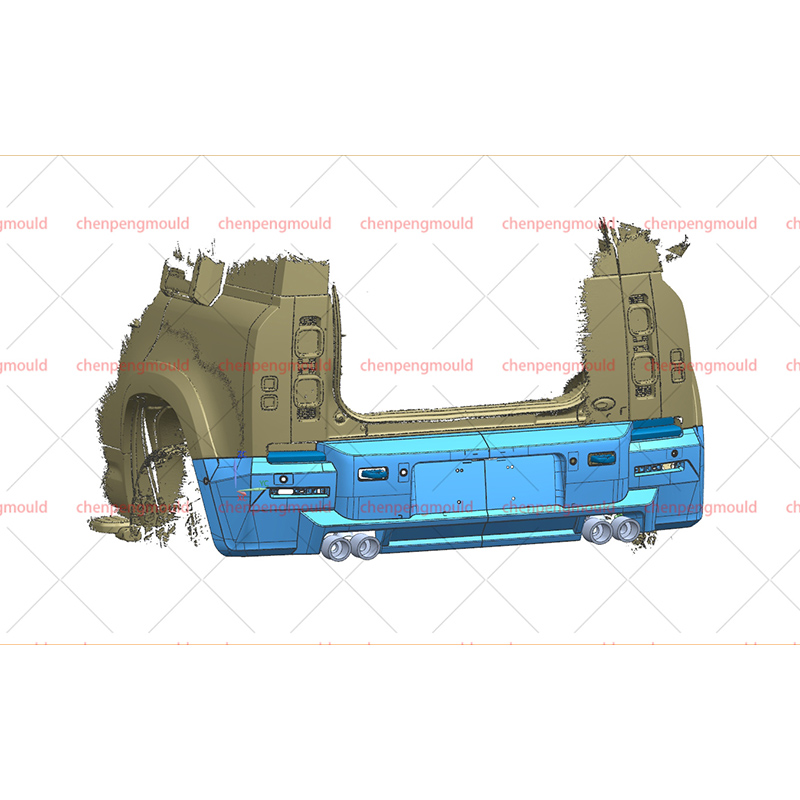

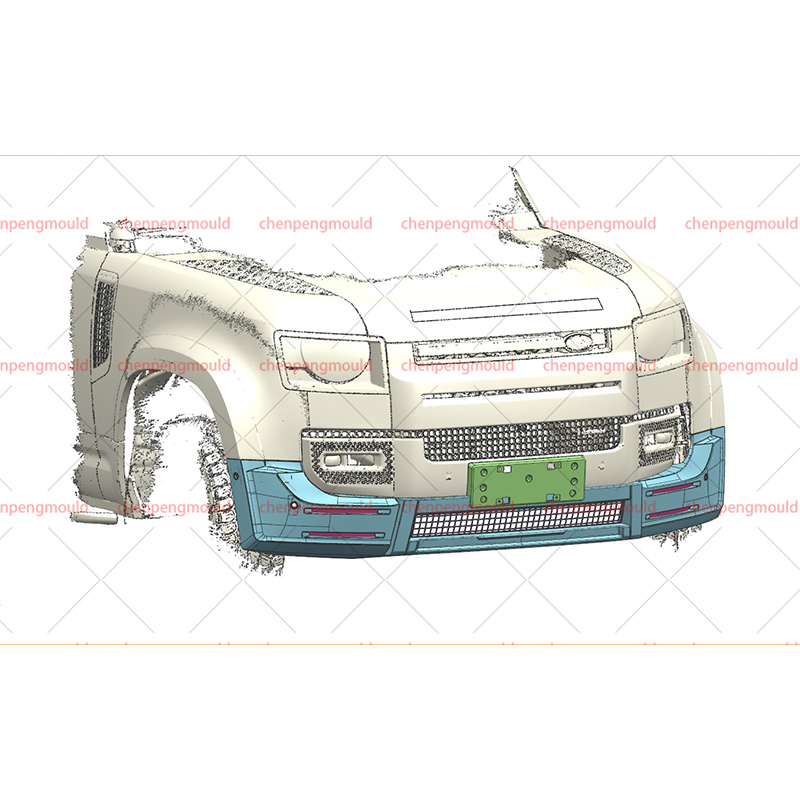

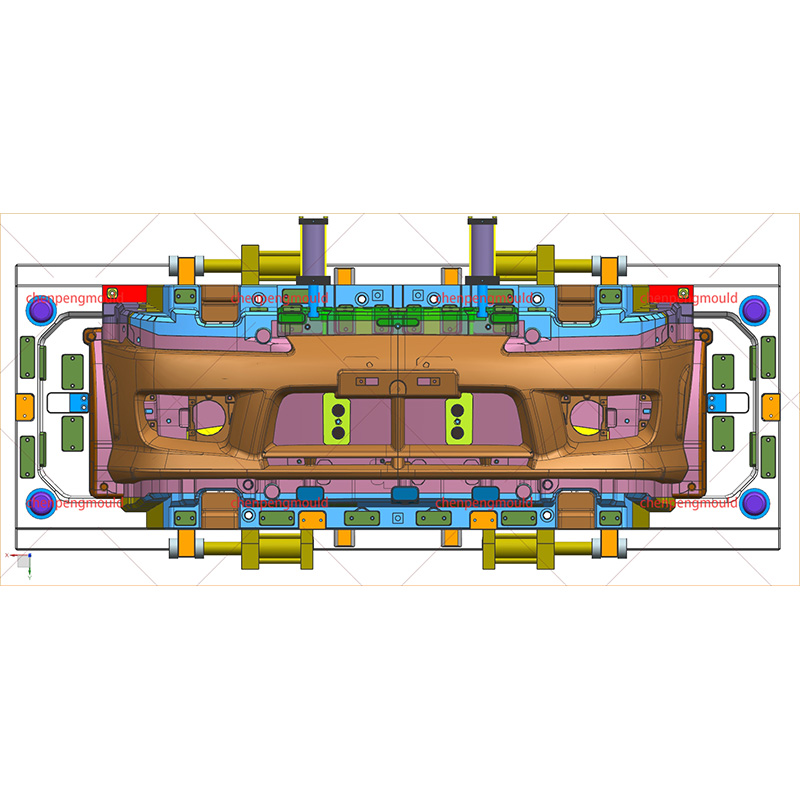

The manufacturing process for front bumper molding typically begins with mold design and development. Engineers create a precise mold based on the vehicle’s bumper geometry and the desired molding profile. Because front bumper moldings must closely match bumper contours, the mold must achieve strict dimensional accuracy. Mold materials are usually hardened steel or aluminum, depending on production volume and surface finish requirements.

Once the mold is completed, injection molding is the common production method. Molten plastic is injected into the mold cavity under controlled pressure and temperature. After cooling, the molded part is ejected and inspected for surface quality, dimensional accuracy, and structural consistency. For flexible moldings produced through extrusion, the material is shaped through a die and then cut to length based on the bumper design.

Secondary processes may include trimming, drilling of mounting holes, surface texturing, painting, or chrome finishing. Quality inspection follows these steps to verify that the molding meets appearance and fitment requirements. Finally, the finished moldings are packaged and shipped either to the bumper assembly line or directly to aftermarket distribution centers.

What are common issues associated with front bumper moldings and how are they addressed?

Several common issues can arise with front bumper moldings during both production and service life. One frequent concern is improper fitment. If the molding does not align precisely with the bumper surface, gaps, lifting edges, or misalignment may occur. These problems are often traced to mold wear, material shrinkage variation, or installation errors. Adjusting mold dimensions, optimizing material selection, and improving installation fixtures can help reduce this risk.

Another issue involves surface aging. Over time, exposure to sunlight, temperature changes, road debris, and cleaning chemicals can cause fading, brittleness, or surface cracking. This is especially noticeable in uncoated plastic moldings. To address this, manufacturers may add ultraviolet stabilizers to the material or apply protective surface coatings that slow down environmental degradation.

Attachment failure is also a recurring concern. Moldings secured with clips or adhesive tapes may loosen due to vibration, thermal expansion, or moisture intrusion. Improved clip design, stronger adhesives, and better surface preparation during installation can enhance long-term attachment reliability.

In the aftermarket, color matching and finish consistency present additional challenges. Replacing a molding on a vehicle that has been exposed to weather for several years may result in visible differences between new and aged components. Some repair centers address this by repainting moldings or treating surrounding bumper surfaces to reduce contrast.

From a manufacturing standpoint, scrap caused by flow lines, sink marks, or warping is another issue that affects production efficiency. These defects can often be minimized by optimizing mold gate design, adjusting cooling channels, and maintaining stable processing conditions.

+86-18357617666

+86-18357617666