These moulds are used in the injection moulding or compression moulding processes, both of which ensure that bumpers meet the required specifications for strength, durability, and aesthetic appeal. While bumper moulds are an essential part of the automotive industry, they come with their own set of advantages and limitations.

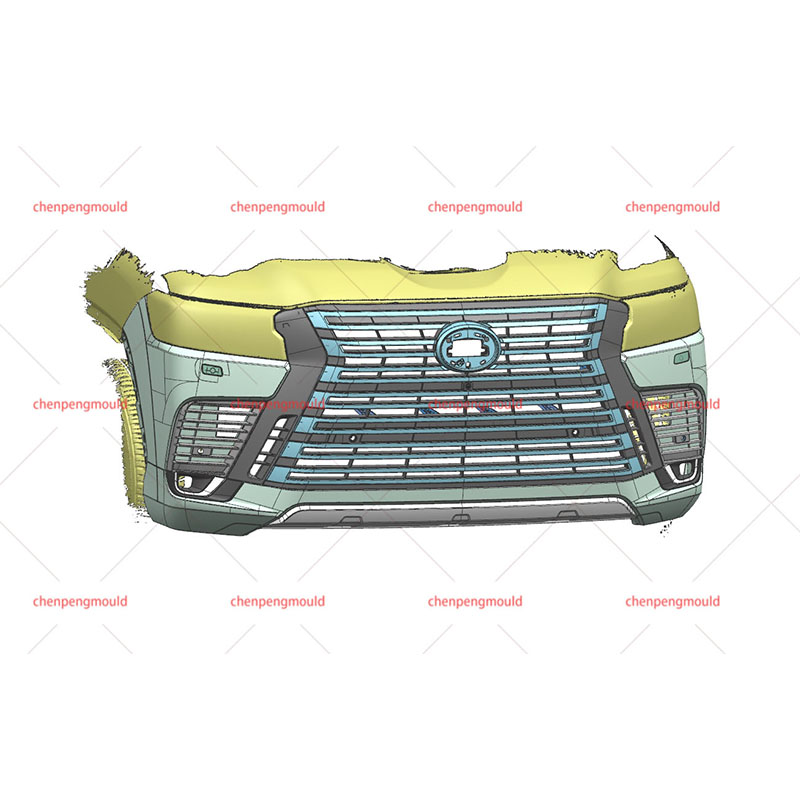

1. What is a Bumper Mould?

The moulding process typically involves injecting heated plastic material into the mould cavity, where it is allowed to cool and take the shape of the bumper. This process is often used for mass production, allowing manufacturers to produce large quantities of identical bumpers efficiently and with high precision.

2. Advantages of Bumper Moulds for Cars

Bumper moulds offer numerous benefits in the production of car bumpers. These advantages make them essential tools for automotive manufacturers, allowing them to produce high-quality bumpers that are functional, durable, and aesthetically appealing.

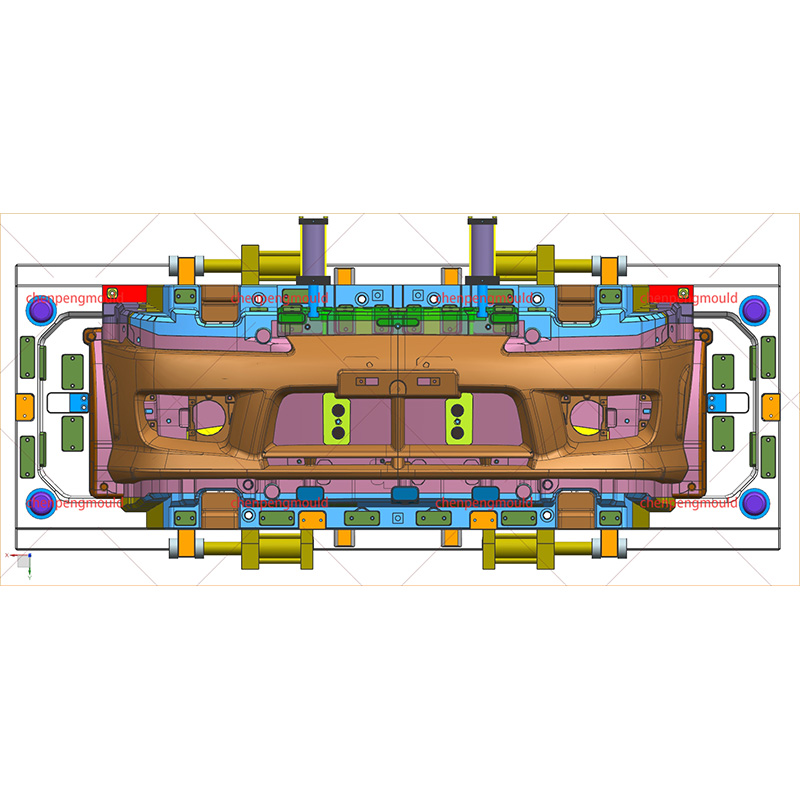

a. Precision and Consistency

One of the key advantages of using bumper moulds is the ability to produce highly precise and consistent parts. The moulding process ensures that every bumper is made to the exact specifications required for the vehicle model. This level of precision is crucial for ensuring that the bumper fits correctly and functions as intended.

Impact Resistance: Precise moulding ensures that bumpers have the correct thickness and reinforcement in high-stress areas, which is critical for their ability to absorb impact during collisions.

Aesthetic Uniformity: Consistency in design allows manufacturers to create bumpers with uniform appearance, enhancing the overall look of the vehicle.

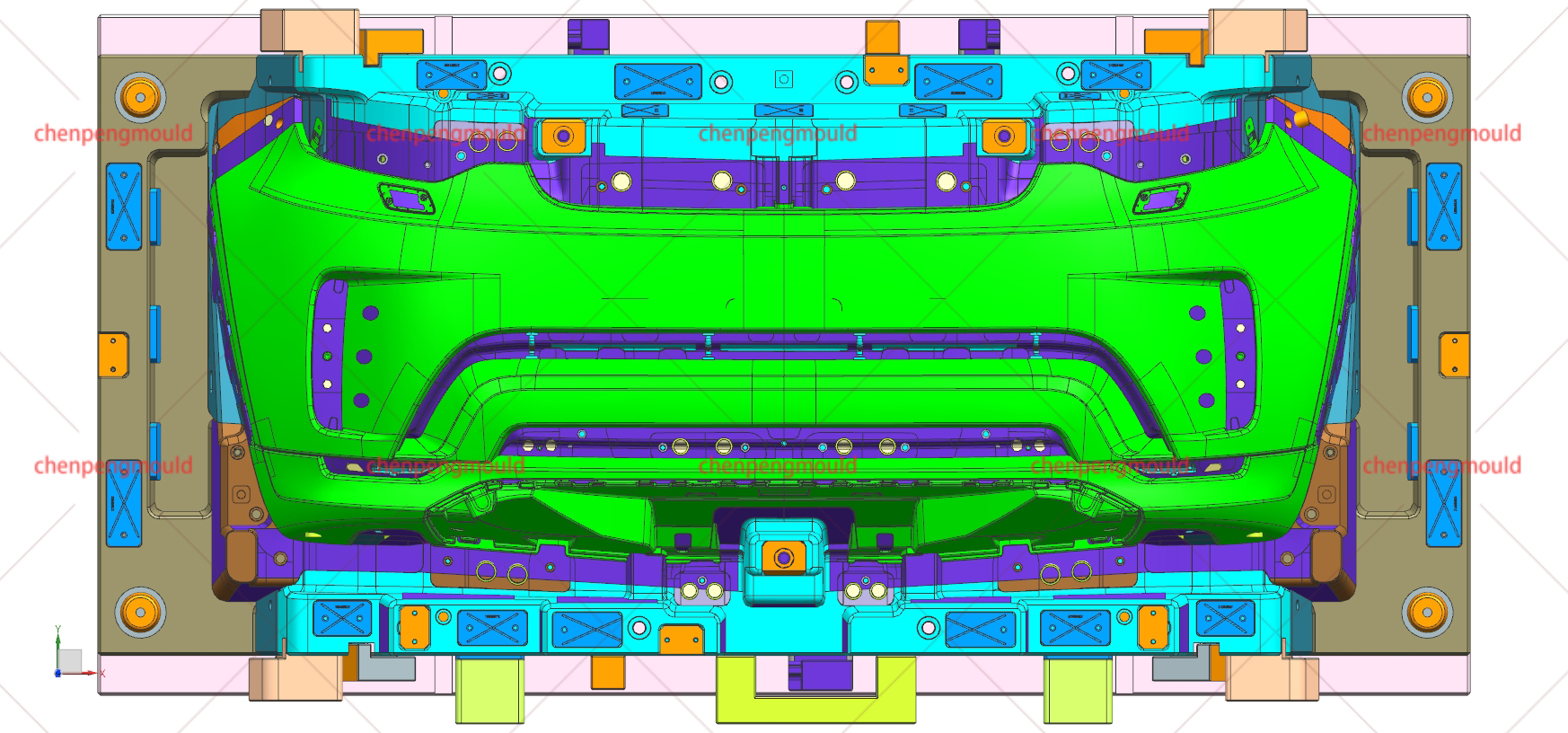

b. Cost-Effective for Mass Production

Bumper moulds are highly cost-effective for mass production. Once the initial mould is created, manufacturers can produce thousands or even millions of bumpers at a relatively low cost per unit. The speed and efficiency of the moulding process help manufacturers achieve economies of scale, making it more affordable to produce bumpers in large quantities.

High Volume Production: The moulding process can be automated, enabling the production of large volumes of bumpers with minimal human intervention.

Reduced Labor Costs: Since the process is automated, the need for manual labor is significantly reduced, helping to lower production costs.

c. Material Versatility

Bumper moulds can be used with a wide variety of materials, allowing manufacturers to choose the material for each application. Popular materials for bumper manufacturing include:

Polypropylene (PP): A common choice for bumpers due to its impact resistance and recyclability.

Thermoplastic Olefins (TPO): Offers a balance of strength, flexibility, and environmental friendliness.

Acrylonitrile Butadiene Styrene (ABS): Known for its durability and smooth surface finish, making it ideal for high-end vehicles.

This versatility allows manufacturers to create bumpers with different performance characteristics, depending on the specific needs of the vehicle.

d. Lightweight and Durable

Plastic bumpers are lightweight compared to their metal counterparts, which helps to reduce the overall weight of the vehicle and improve fuel efficiency. Despite their light weight, plastic bumpers can still be incredibly durable and able to withstand the rigors of everyday driving, including minor impacts and weather conditions.

Fuel Efficiency: Lightweight bumpers reduce the overall weight of the vehicle, contributing to better fuel economy.

Durability: Plastic bumpers made using high-quality materials are highly resistant to corrosion, rust, and UV damage.

3. Limitations of Bumper Moulds for Cars

While bumper moulds offer several advantages, they also come with certain limitations. Understanding these limitations is essential for automotive manufacturers to make informed decisions about their production processes and material selection.

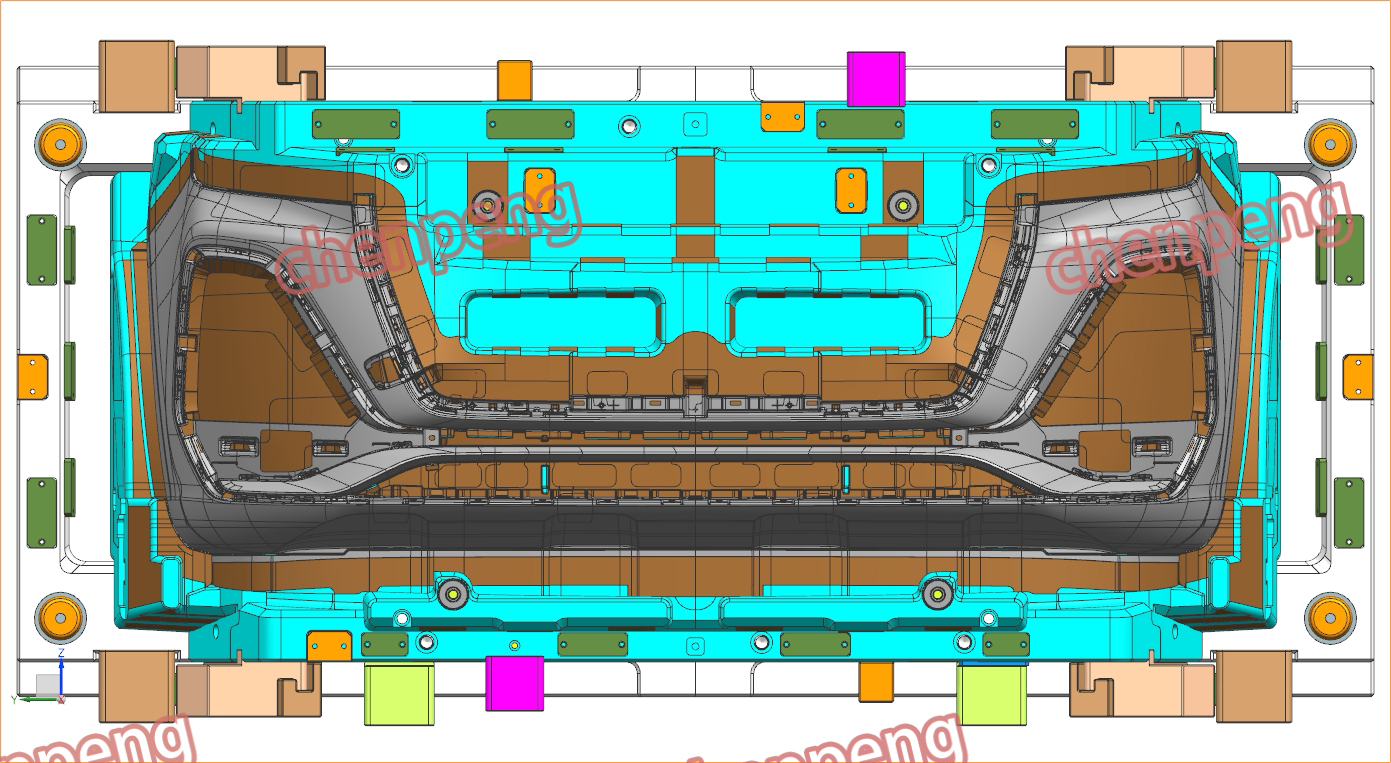

One of the major limitations of using bumper moulds is the high initial cost associated with creating the moulds. Moulds for car bumpers are typically made from high-strength materials such as steel or aluminum, which can be expensive to produce. The design and engineering of the moulds also require significant expertise and time.

Capital Investment: For manufacturers, the upfront cost of designing and manufacturing the moulds can be a significant barrier, especially for smaller businesses or those producing low volumes of bumpers.

Long Times: Creating a custom bumper mould can take weeks or even months, depending on the complexity of the design and the material used.

+86-18357617666

+86-18357617666