Bumper moulds are crucial tools in automotive manufacturing, enabling the production of vehicle bumpers that meet both safety standards and aesthetic requirements. A modified bumper mould provides flexibility for customization, allowing manufacturers to produce designs that accommodate different car models, materials, and finish options. Understanding the types of modified bumper moulds and the options available helps automotive engineers, designers, and manufacturers make informed decisions for production efficiency and product quality.

Types of Modified Bumper Moulds

Modified bumper moulds can be classified based on design, production method, and intended material. Each type serves specific manufacturing needs and affects the final bumper quality.

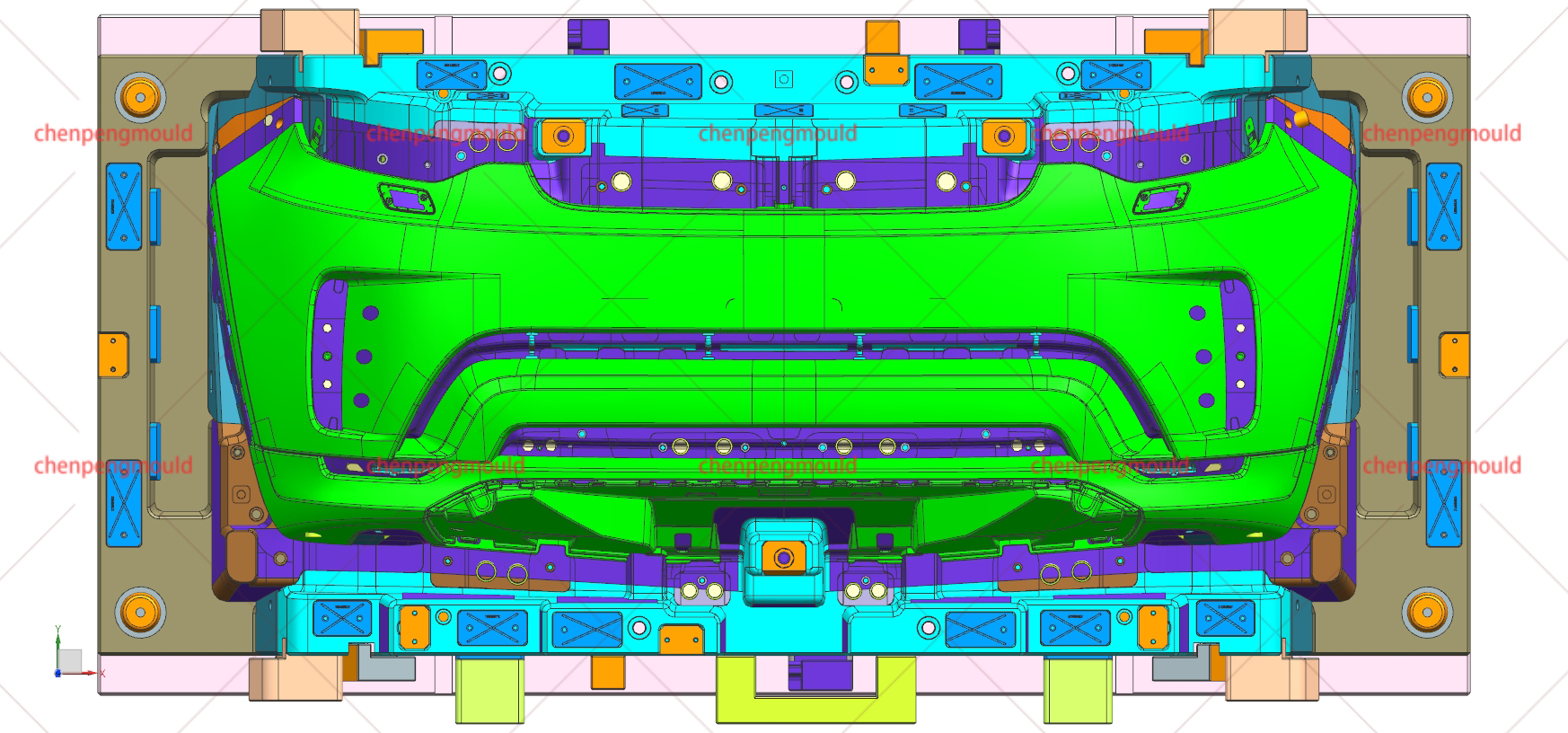

Single-piece moulds: Single-piece moulds produce a complete bumper in one molding cycle. This type is efficient for high-volume production and reduces assembly steps. They are suitable for designs with simple contours and minimal surface details.

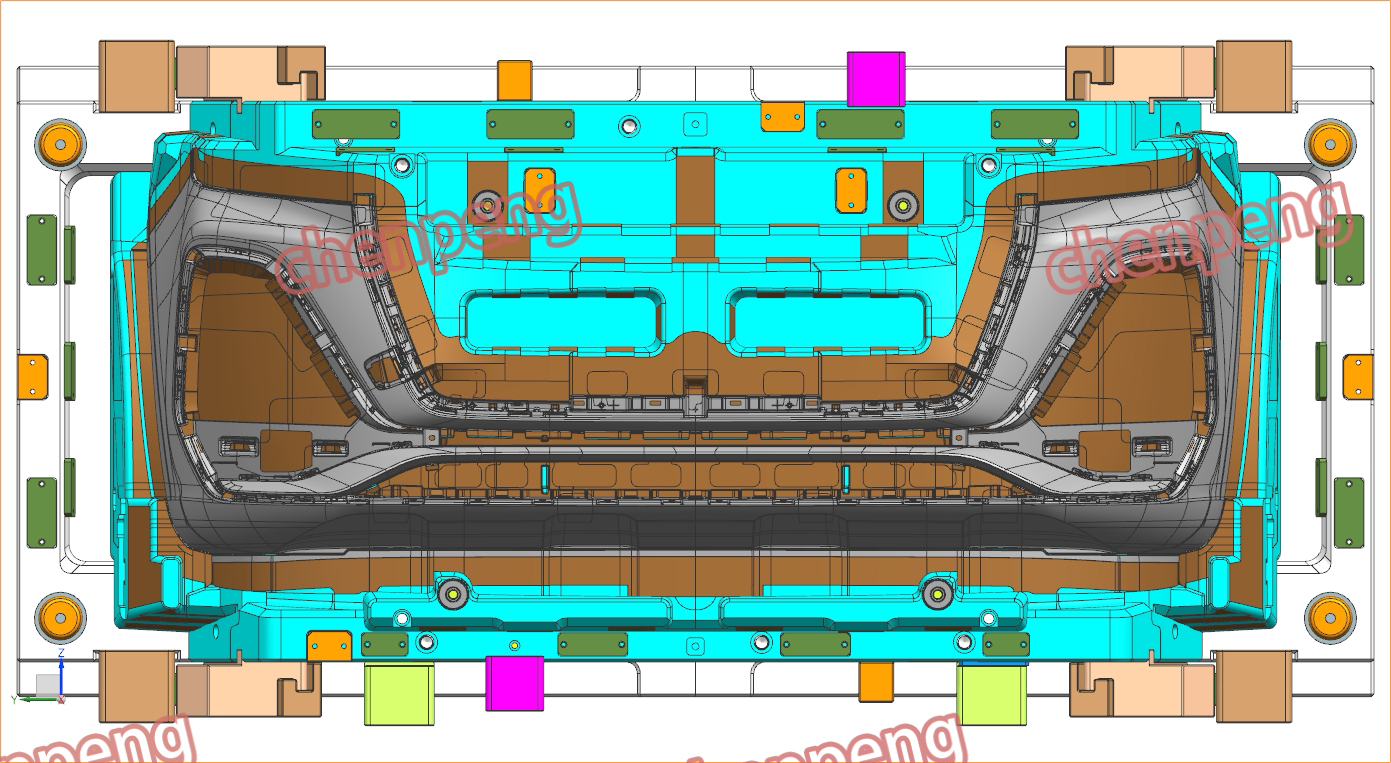

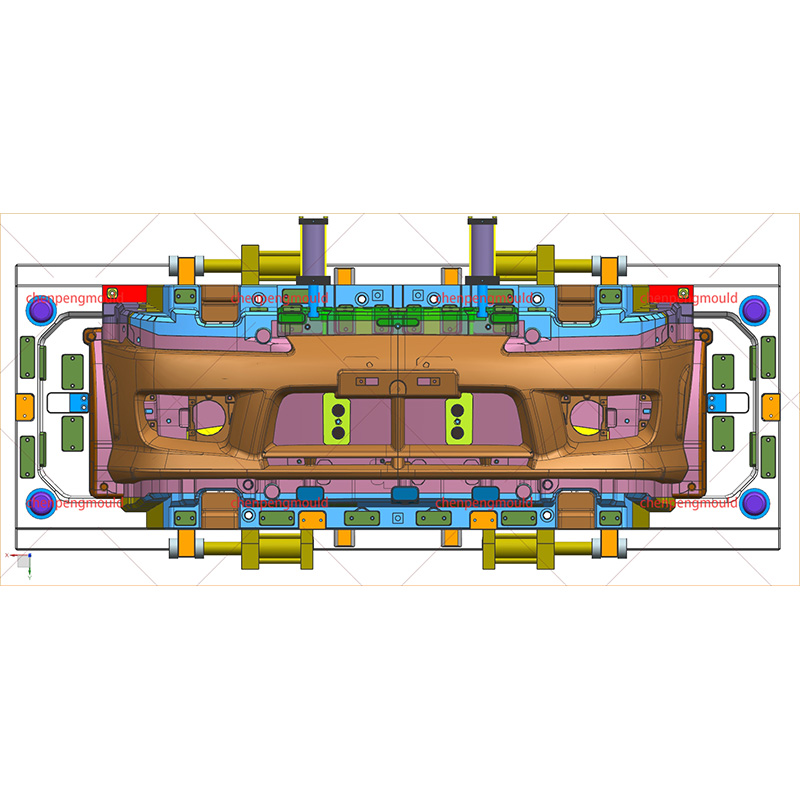

Multi-piece moulds: Multi-piece or sectional moulds divide the bumper into separate components that are later assembled. This type is ideal for complex designs, including intricate curves, vents, or additional styling features. Multi-piece moulds allow easier maintenance and part replacement if a section becomes damaged.

Hot runner moulds: Hot runner moulds feature a heated channel system that keeps plastic molten until injection, reducing waste and improving cycle time. These moulds are suitable for high-precision bumpers that require uniform thickness and smooth surface finishes.

Cold runner moulds: Cold runner moulds rely on standard runners that solidify along with the part, which may require trimming after production. They are often more cost-effective for small-scale manufacturing or prototypes.

Hydraulic and mechanical moulds: Some modified bumper moulds include hydraulic or mechanical systems for ejecting the finished part or controlling the mould movement. Hydraulic systems offer smooth operation for large or complex bumpers, while mechanical systems are simpler and suitable for smaller designs.

Selecting the right type depends on production volume, bumper design complexity, and available manufacturing resources.

Material Options for Modified Bumper Moulds

Material choice is another critical factor for modified bumper moulds, as it affects durability, cost, and compatibility with different bumper materials.

Steel moulds: High-quality steel is commonly used due to its strength, wear resistance, and ability to withstand high injection pressures. Steel moulds are ideal for long production runs and consistent output quality.

Aluminum moulds: Aluminum is lighter and easier to machine than steel, making it suitable for prototype or low-volume production. While less durable than steel, aluminum moulds allow for faster adjustments and lower tooling costs.

Coated moulds: Some moulds include surface coatings, such as nickel or chrome, to improve wear resistance, reduce friction, and enhance the smoothness of the finished bumper. Coated moulds also facilitate easier cleaning and maintenance.

Hybrid moulds: Hybrid moulds combine steel and aluminum components to balance strength and flexibility. For example, critical areas like the cavity may be steel, while secondary components use aluminum to reduce weight and cost.

Choosing the appropriate material ensures the mould maintains precision, supports consistent production, and reduces downtime for repairs or adjustments.

Functional Options for Modified Bumper Moulds

Beyond type and material, modified bumper moulds can include functional options that enhance production efficiency and product quality.

Adjustable cavities: Some moulds allow adjustments in the cavity to produce bumpers of slightly different sizes or styles without creating a new mould. This is useful for producing different trims or model variations.

Interchangeable inserts: Inserts can be replaced to change the design features of the bumper, such as vents, grills, or surface textures. This option reduces tooling costs when multiple designs are needed.

Cooling systems: Integrated cooling channels help maintain consistent temperatures during injection, reducing warping or defects in the final bumper. Optimized cooling improves cycle times and overall production efficiency.

+86-18357617666

+86-18357617666