What are the components of a car bumper mold?

A car bumper injection mold is a large, multi-part assembly typically made from tool steel. Its main components can be grouped by function:

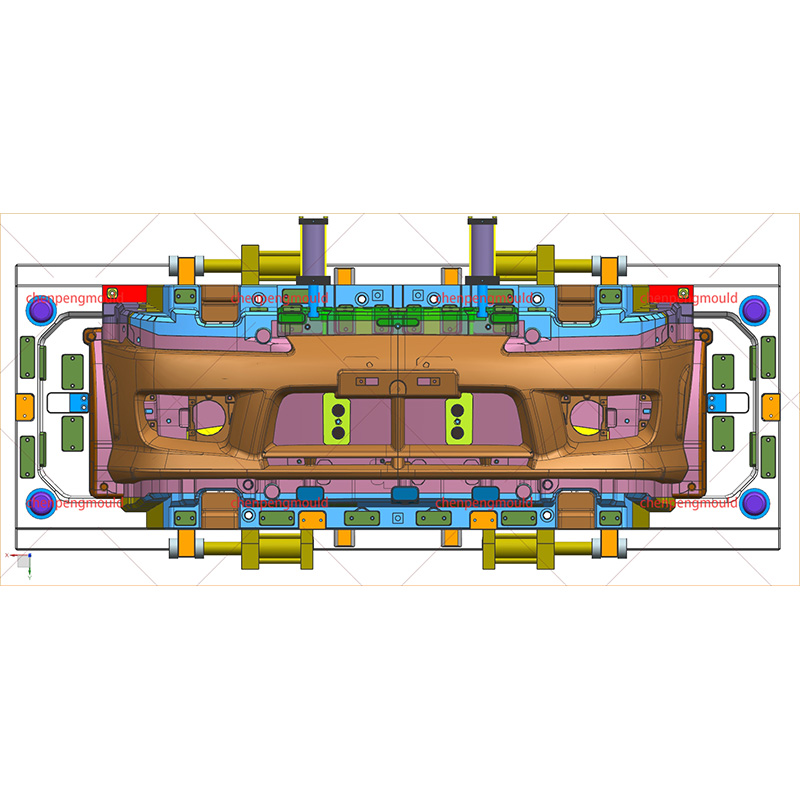

Mold Base: This is the structural frame, consisting of a fixed half (mounted to the injection molding machine's stationary platen) and a moving half (mounted to the moving platen). It houses all other components and ensures alignment via guide pins and bushings.

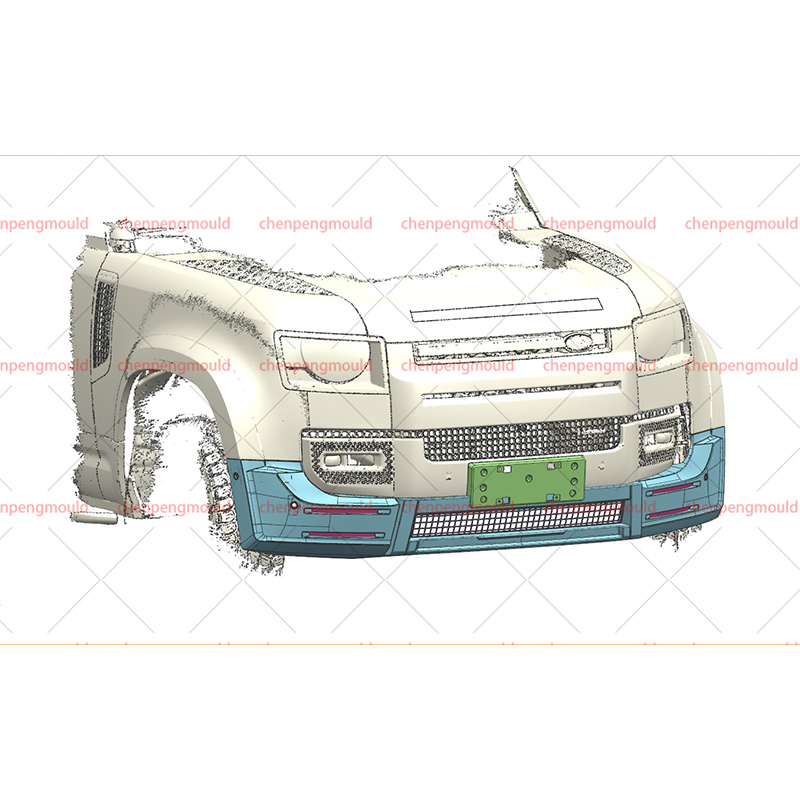

Cavity and Core: These are the negative impressions that form the bumper's shape. The cavity forms the bumper's outer, aesthetic surface (Class A surface). The core forms the inner, structural surface with ribs and mounting points. They are machined from hardened steel blocks.

Gating and Runner System: This is the network of channels that deliver molten plastic from the molding machine's nozzle into the cavity. It includes the sprue (main entry channel), runners (distribution channels), and gates (the controlled entry points into the cavity itself).

Cooling System: A network of drilled channels within the mold blocks through which temperature-controlled water circulates. This system extracts heat from the molten plastic to solidify it efficiently, dictating the production cycle time.

Ejection System: After the plastic solidifies, this mechanism pushes the finished part out of the mold. It consists of ejector pins (which contact the part), ejector plates, and return pins to retract the system as the mold closes.

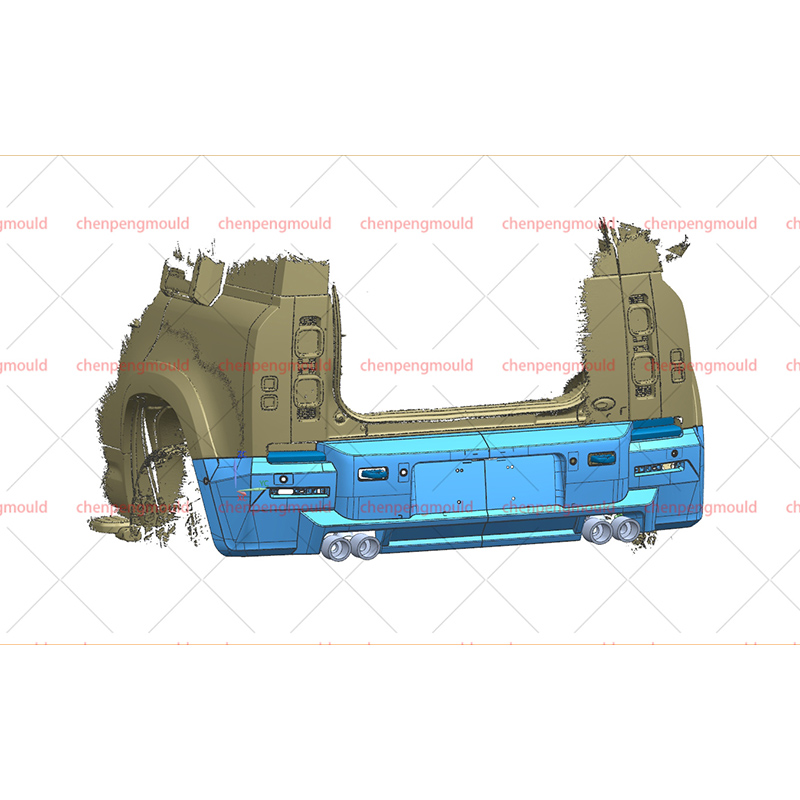

Slides and Lifters: These are movable mold sections that form undercuts—features like wheel arch openings or mounting hooks that would otherwise lock the part inside the mold. They move at an angle to clear the part during ejection.

Venting: Thin channels or gaps at the mold parting line that allow trapped air to escape as molten plastic fills the cavity, preventing defects like burns or short shots.

Why does a car bumper mold exist?

The existence of the bumper mold is driven by the requirements of mass-producing a specific automotive component.

Enabling High-Volume Production

The primary purpose is to enable the manufacture of hundreds of thousands of identical bumper parts. Injection molding, facilitated by the mold, is a high-speed, repeatable process. Once the mold is installed in a press, a new bumper can be produced every 60 to 120 seconds, meeting the demanding output rates of automotive assembly lines.

Achieving Complex Geometry and Integration

A modern bumper is not a simple shield; it is an integrated assembly that often houses fog lights, sensor cavities, grille openings, and aerodynamic features. The mold is engineered to form this complex geometry, including intricate internal ribbing for strength and mounting points for other components, in a single manufacturing step.

Ensuring Consistent Surface Quality

The mold cavity's surface is polished to a mirror finish and often textured via chemical etching or laser engraving. This directly replicates the bumper's final aesthetic surface, ensuring consistency in gloss, grain, and appearance across every part produced, which is critical for vehicle quality.

Disadvantages of car bumper mold

Despite being essential, the bumper mold presents significant challenges and limitations.

The high initial cost and lead time are primary disadvantages. Designing and machining a large, complex mold from tool steel is a capital-intensive process requiring months of engineering and skilled labor. This makes the mold a major upfront investment and makes design changes after tooling is complete costly and time-consuming.

The mold is subject to significant wear and maintenance demands. The high injection pressures and clamping forces, along with the abrasive nature of some filled plastics, gradually erode polished surfaces and moving components like slides and ejector pins. Regular maintenance, cleaning, and repairs are necessary to prevent part defects and mold failure, contributing to ongoing operational costs.

There is limited design flexibility post-production. Any change to the bumper's shape, even a minor one, typically requires modifying the hardened steel mold—a difficult and expensive process—or building an entirely new one. This inflexibility contrasts with more adaptable manufacturing methods like additive manufacturing or fabrication.

+86-18357617666

+86-18357617666