Types of Materials Used in Modified Bumper Molding

The material used in modified bumper molding is a critical factor in determining the durability, weight, and overall performance of the bumper. A variety of materials can be used in the molding process, each offering distinct advantages depending on the desired characteristics of the finished bumper.

Polypropylene (PP): This is one of the common materials used in bumper molding. Polypropylene is a lightweight and cost-effective thermoplastic that offers good impact resistance. It can also be easily modified with additives to improve its strength and flexibility. Polypropylene bumpers are widely used in standard vehicles due to their balance of performance and cost.

Polyurethane (PU): Used for more flexible bumpers, polyurethane is known for its high impact resistance and ability to absorb energy during a collision. It is often found in high-performance vehicles, where the bumper needs to handle heavy impacts while maintaining shape and appearance.

Acrylonitrile Butadiene Styrene (ABS): ABS is a common material for modifying bumpers to achieve a more rigid structure. It is durable, easy to mold, and provides a smooth finish. ABS bumpers can be modified to suit specific requirements for impact resistance and appearance.

Thermoplastic Olefins (TPO): TPO is another popular material used in modified bumper molding. It is known for its durability, resistance to UV radiation, and recyclability. It is commonly used in bumpers that require a balance between strength, flexibility, and environmental performance.

Each material type offers unique benefits, and the choice of material will depend on the vehicle’s design goals, environmental factors, and safety requirements.

Design Considerations in Modified Bumper Molding

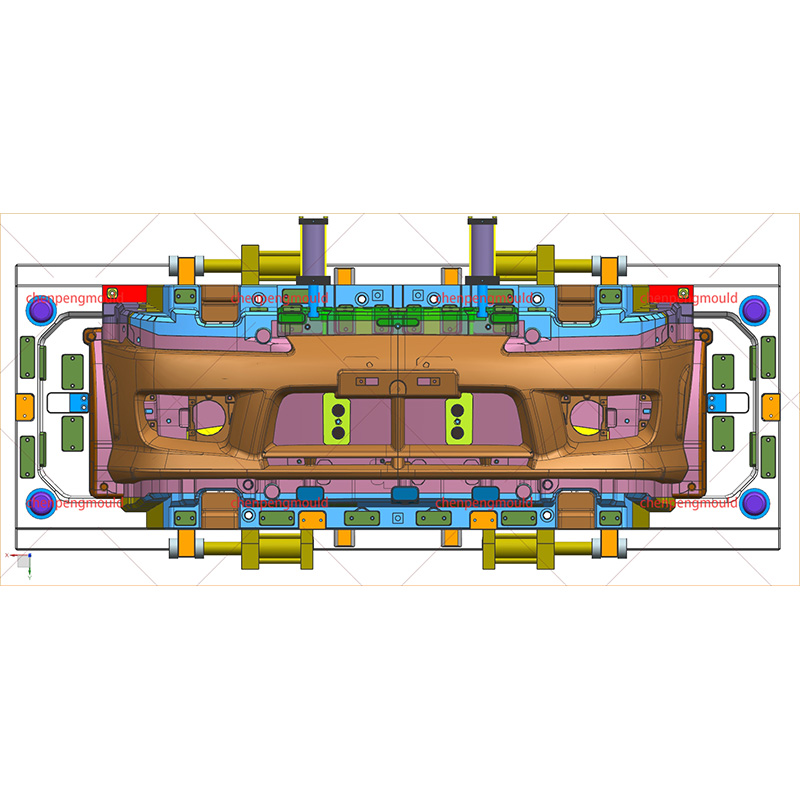

When modifying bumper molds, several design factors must be taken into account to ensure that the final product meets both functional and aesthetic requirements. The design considerations include the bumper's shape, size, weight, and how it integrates with the vehicle’s body.

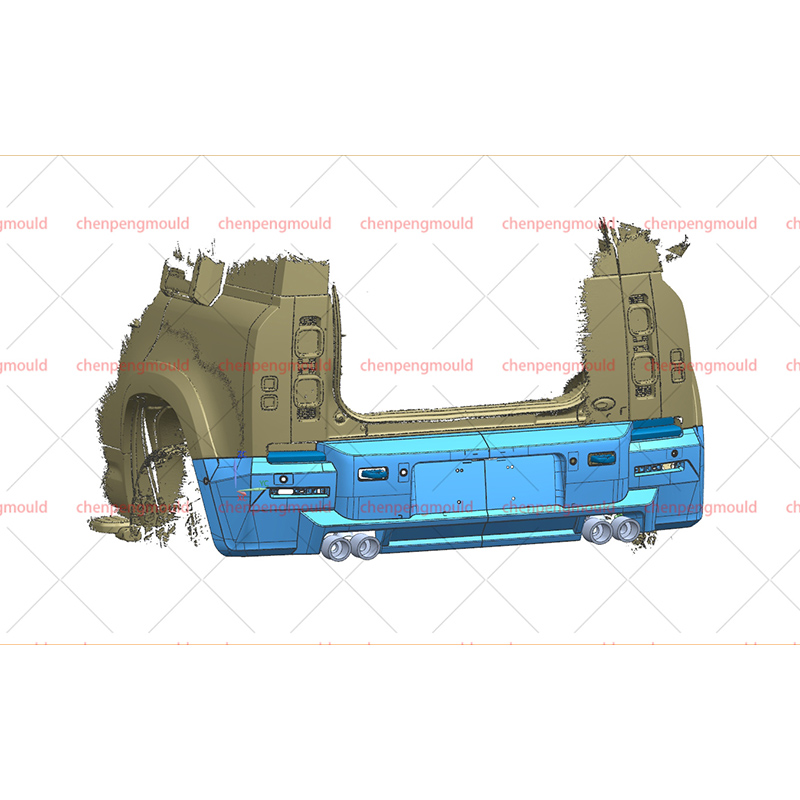

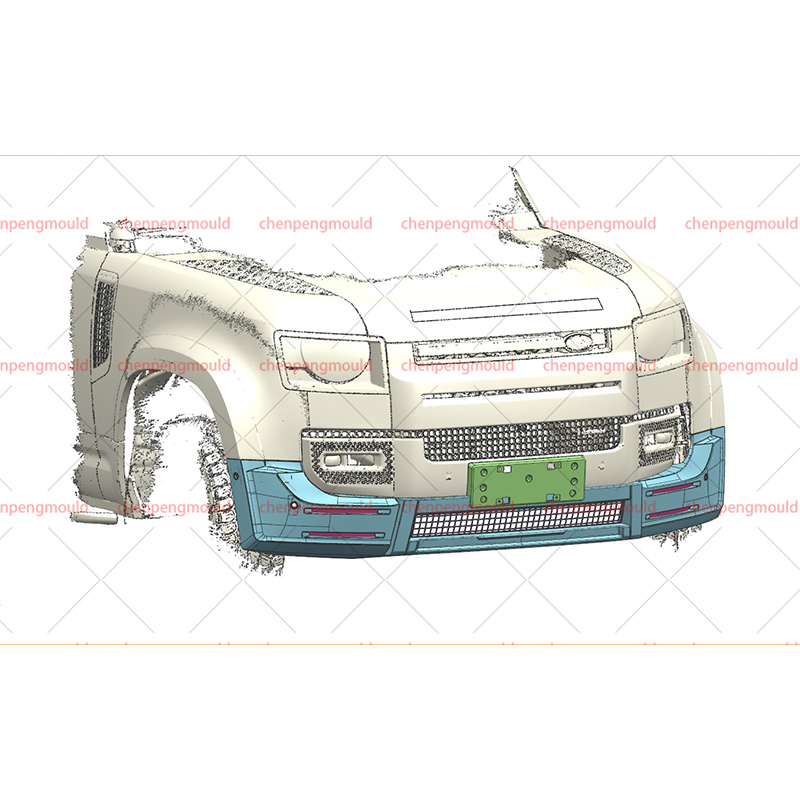

Shape and Fit: The bumper must be designed to fit the specific dimensions of the vehicle it is intended for. Modifications are often made to ensure that the bumper aligns perfectly with the vehicle’s front or rear end. This alignment is crucial for both the appearance and the overall structural integrity of the vehicle.

Impact Resistance: The design of the bumper mold must account for the bumper’s ability to absorb and dissipate impact energy. Modified bumpers are often designed to include crumple zones, which deform upon impact to reduce the force transmitted to the vehicle’s frame and passengers. This is an essential consideration for safety regulations.

Aerodynamics: In some cases, bumpers are designed with aerodynamic considerations to reduce drag or enhance vehicle performance. Modifications may be made to the bumper’s shape to improve airflow, reduce fuel consumption, or enhance vehicle handling.

Aesthetic Appeal: The bumper's appearance is also an important design factor. Many modified bumpers are designed to complement the vehicle’s overall aesthetic, whether by providing a sleek, sporty look or a more rugged, off-road appearance. Customizable elements such as color, texture, and finish are often integrated into the design during the modification process.

Advantages of Modified Bumper Molding

Modified bumper molding offers several key benefits for both car manufacturers and consumers. These advantages are particularly important in ensuring that bumpers fulfill their primary functions of protection, aesthetics, and vehicle integration.

Improved Safety Features: One of the primary advantages of modifying bumper molds is the ability to enhance safety features. Modified bumpers can be designed to better absorb impact and protect both the vehicle occupants and pedestrians in the event of a collision. This is especially important in meeting stringent safety standards in the automotive industry.

Customization and Aesthetic Enhancement: Modified bumpers provide a high degree of customization for car manufacturers and consumers. The ability to adjust the shape, size, and materials allows for the creation of bumpers that not only enhance vehicle performance but also contribute to the overall design vision of the car. This is especially important for luxury, sports, or specialty vehicles, where the bumper design plays a significant role in the vehicle's appearance.

Cost Efficiency in Production: Using modified molds can bring about cost savings in production. By optimizing the design and material properties of the bumper, manufacturers can reduce material waste, improve production efficiency, and create parts that require less post-production work. This can be especially beneficial in high-volume manufacturing settings where cost control is a key consideration.

Durability and Performance: Modified bumper molding can result in bumpers that are more durable and perform better under various conditions. By selecting appropriate materials and designing bumpers for specific vehicle needs, manufacturers can create parts that withstand harsh conditions, including temperatures, UV exposure, and mechanical stress. This enhances the longevity and reliability of the bumper.

+86-18357617666

+86-18357617666