One of the defining characteristics of modified bumper molding is the use of advanced materials that improve performance and longevity compared to traditional bumpers. Typically, modified bumpers employ engineered thermoplastics or composite materials, such as polypropylene (PP) blends, thermoplastic olefins (TPO), and thermoplastic elastomers (TPE).

Impact Resistance: These materials exhibit impact resistance, allowing the bumper to absorb shocks more effectively during minor collisions or bumps. The ability to flex and return to the original shape without cracking is vital in reducing repair costs and maintaining vehicle safety.

Lightweight Nature: Modified bumper moldings are generally lighter than older metal or rigid plastic counterparts. This weight reduction contributes positively to overall fuel efficiency and vehicle handling, especially as automakers focus on reducing emissions and enhancing performance.

Weather and UV Resistance: Advanced polymers used in modified bumper moldings are often treated or inherently resistant to UV radiation, moisture, and temperature fluctuations. This ensures that the bumper maintains its color, texture, and mechanical properties even after prolonged exposure to harsh environmental conditions.

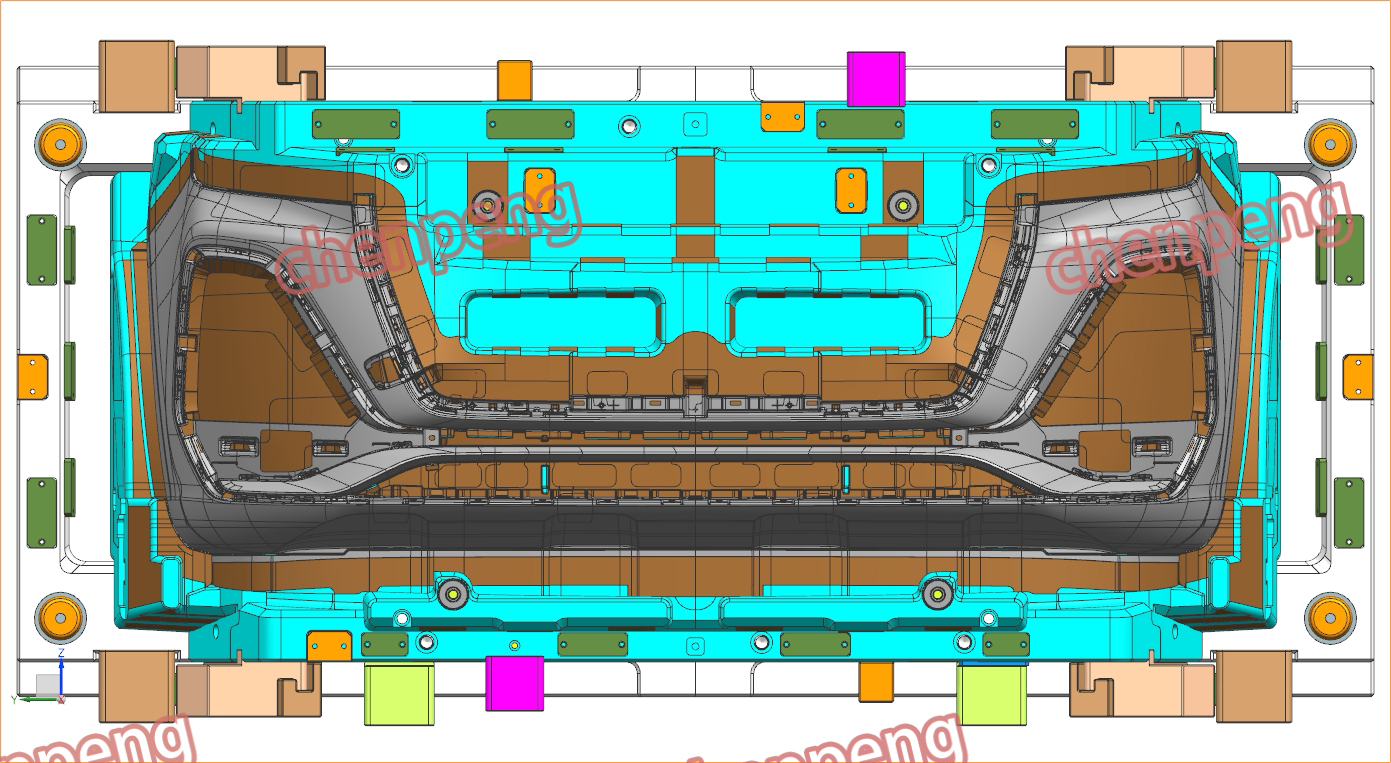

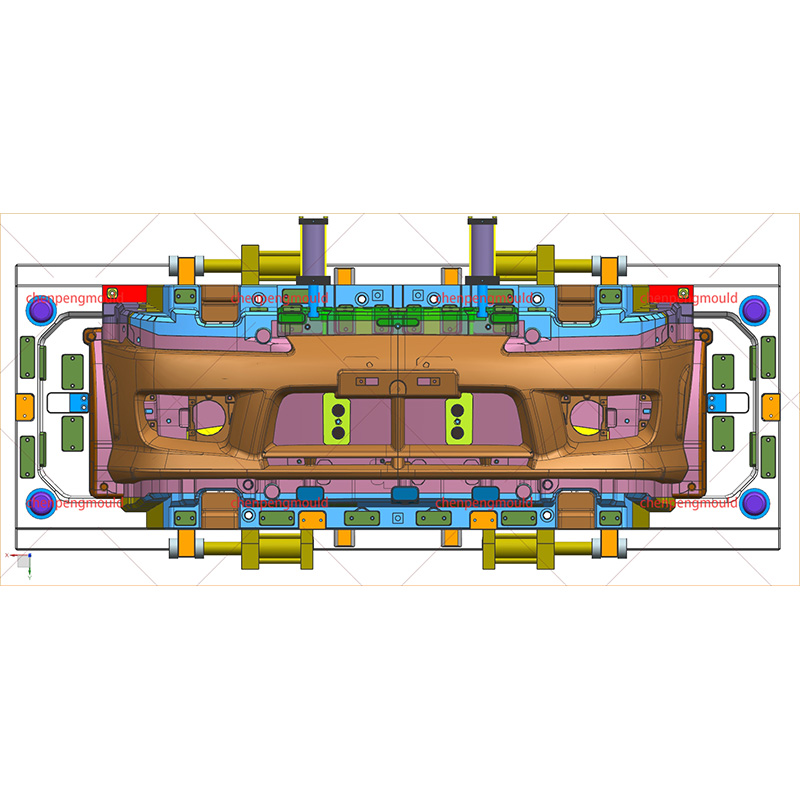

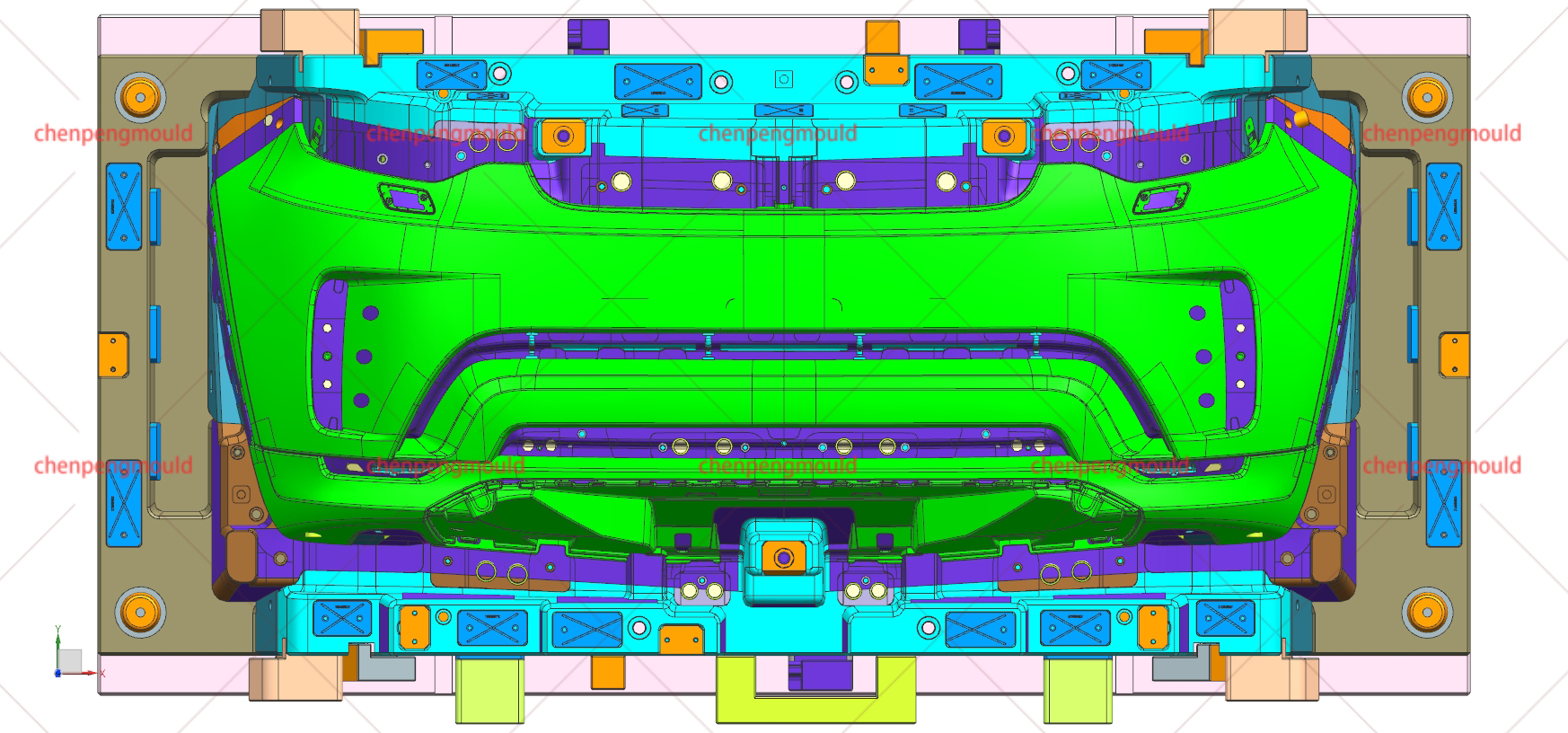

The characteristics of modified bumper molding are also shaped by improvements in manufacturing processes. Modern molding techniques such as injection molding, compression molding, and reaction injection molding (RIM) allow for greater precision, consistency, and complexity in design.

Complex Shapes and Fine Details: Modified bumper moldings can be designed with intricate patterns, integrated mounting points, and aerodynamic contours. This allows manufacturers to create bumpers that not only protect but also enhance the vehicle's overall aesthetics and airflow dynamics.

High Dimensional Accuracy: Advanced molding technologies provide tight tolerances, ensuring that the bumper fits precisely with adjoining vehicle panels and components. This reduces gaps, rattling, and installation difficulties, contributing to a higher-quality finished product.

Surface Finish: Modified bumper moldings can feature smooth or textured surfaces directly from the mold, reducing or eliminating the need for additional finishing processes. The surface can be designed to better resist scratches or fading, maintaining a fresh appearance over time.

Modern modified bumper moldings serve purposes beyond mere impact protection and decoration. Their design now accommodates various functional components, reflecting the increased technological complexity of contemporary vehicles.

Sensor and Camera Integration: Modified bumpers are often engineered to include provisions for parking sensors, proximity sensors, cameras, and radar systems. These integrated features support advanced driver assistance systems (ADAS), such as automatic parking, collision avoidance, and adaptive cruise control.

Energy Absorption Structures: Behind the outer molding, energy-absorbing materials like foam cores or honeycomb structures are commonly used. These layers help dissipate impact forces during collisions, reducing damage to the vehicle frame and enhancing occupant safety.

Aerodynamics: Modified bumper moldings are carefully sculpted to improve the vehicle's aerodynamic performance. By managing airflow around the vehicle, the bumper helps reduce drag, which can improve fuel efficiency and reduce wind noise.

Another important characteristic of modified bumper molding is its enhanced durability, which directly influences vehicle maintenance and lifespan.

Scratch and Dent Resistance: The advanced polymers used in modified bumpers are more resistant to minor abrasions, dents, and chips compared to traditional materials. This resistance helps maintain the vehicle's visual appeal over time and reduces the need for frequent repairs.

Ease of Repair: Modified bumper moldings are designed to be easier to repair or replace. Some materials allow for heat or solvent-based repairs, while modular design elements enable quick replacement of damaged sections without changing the entire bumper assembly.

Corrosion Resistance: Unlike older metal bumpers, modified bumper moldings do not rust or corrode. This eliminates a common source of long-term degradation and helps extend the vehicle's overall service life.

+86-18357617666

+86-18357617666