Plastic bumper molds play an important role in automotive manufacturing. Because bumpers are exterior parts that influence both the appearance and safety performance of a vehicle, the molds used to produce them must meet high requirements for accuracy, durability, and production efficiency. To serve different vehicle designs and materials, plastic bumper molds are classified using multiple criteria.

1. Classification by Mold Structure

Different structural designs allow bumper molds to meet varying complexity and production needs. The major types include:

(1) Single-cavity bumper molds

These molds produce one bumper per cycle and are widely used in medium- and high-volume automotive production. For example, many passenger cars, such as compact sedans, rely on single-cavity molds to achieve consistent product quality. Because each cycle forms one component, manufacturers can easily track dimensional accuracy and ensure stable output.

(2) Multi-cavity bumper molds

Multi-cavity molds can form more than one product at a time, improving production efficiency. They are often used for smaller protective components such as rear bumper trim or corner protectors. Although less common for full-size bumpers due to part size, this type supports high-output environments like commercial vehicle plants where identical bumper components are needed rapidly.

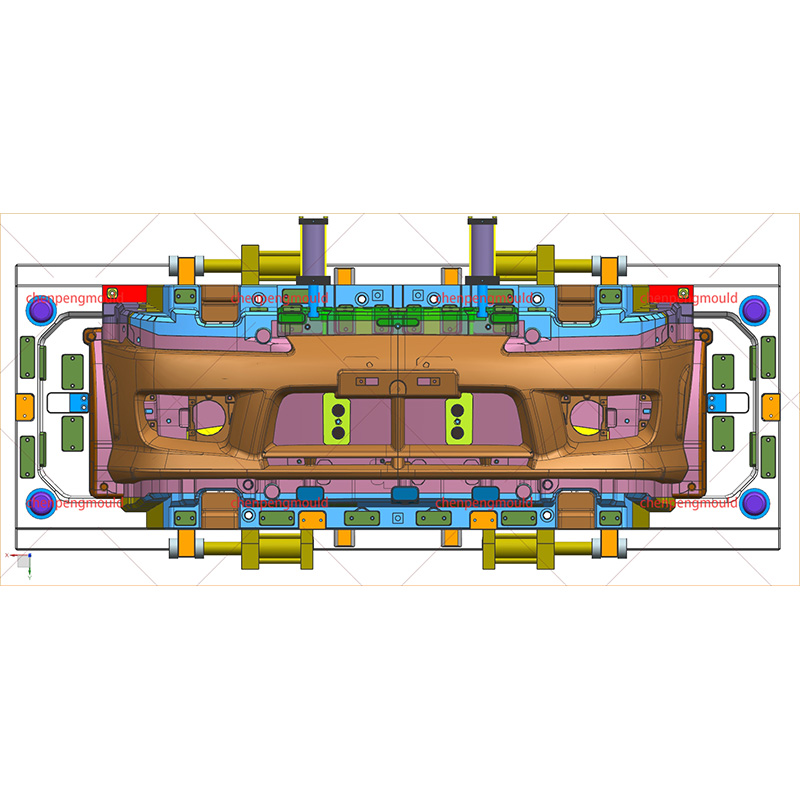

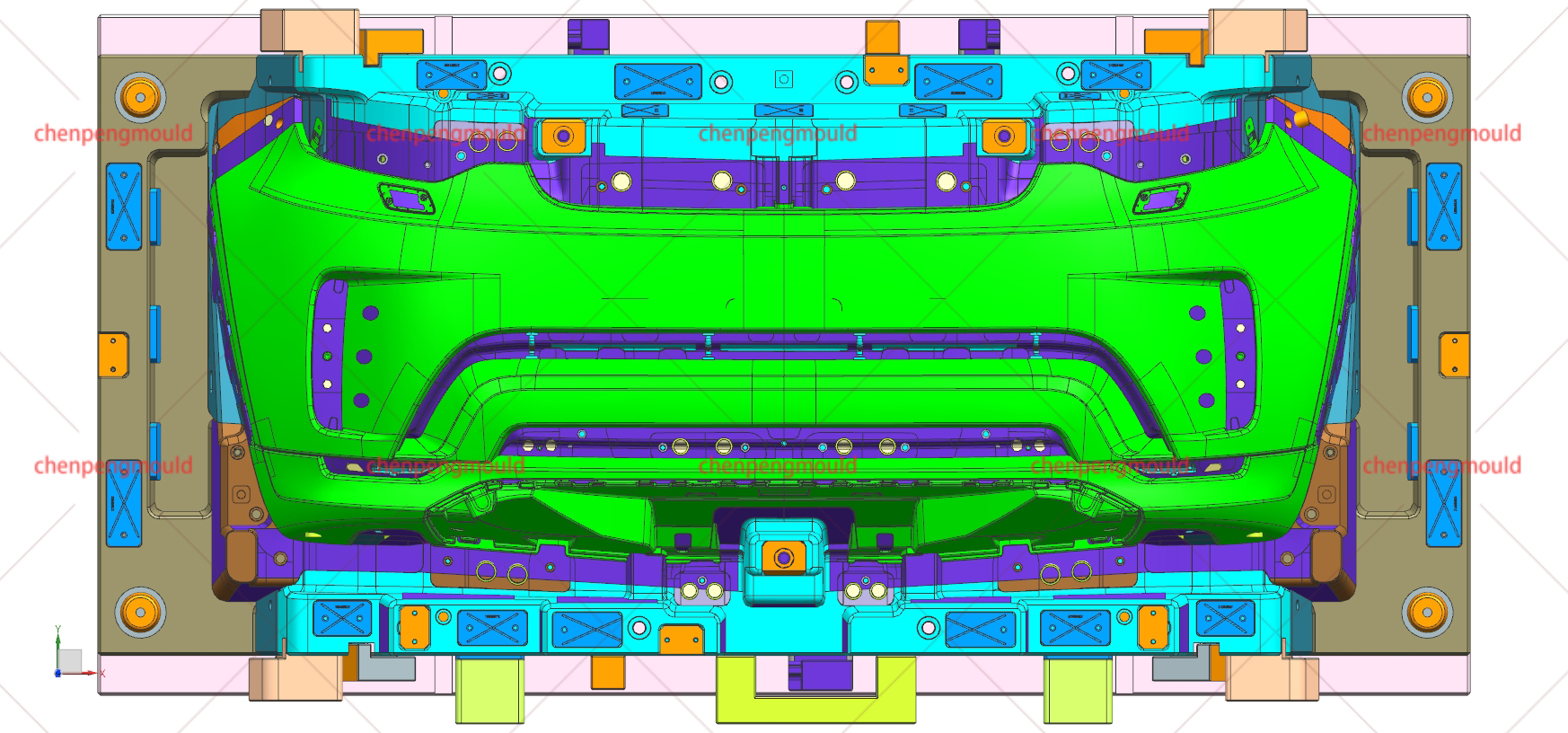

(3) Hot-runner bumper molds

Hot runners keep molten plastic flowing inside heated channels, reducing material waste and improving surface finish. This technology is frequently adopted for modern SUV and high-end vehicle bumpers that require precise contour and smooth appearance. The reduced scrap rate also helps control production costs.

(4) Cold-runner bumper molds

Cold-runner molds allow materials to solidify in the runner system. While they may increase waste and trimming work, they remain an option for prototypes or lower production volumes due to their simplicity and lower tooling cost.

2. Classification by Processing Method

The way a bumper mold is manufactured also affects its classification and suitability:

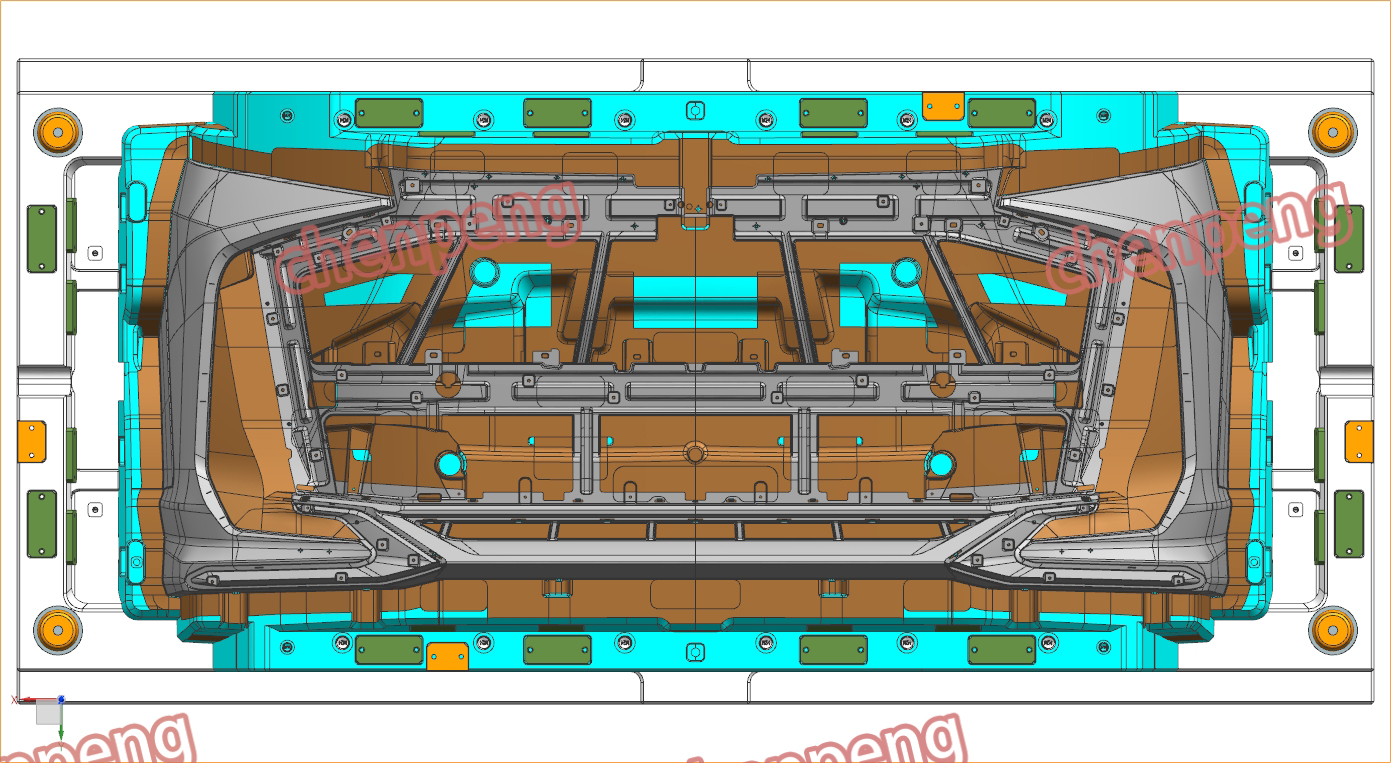

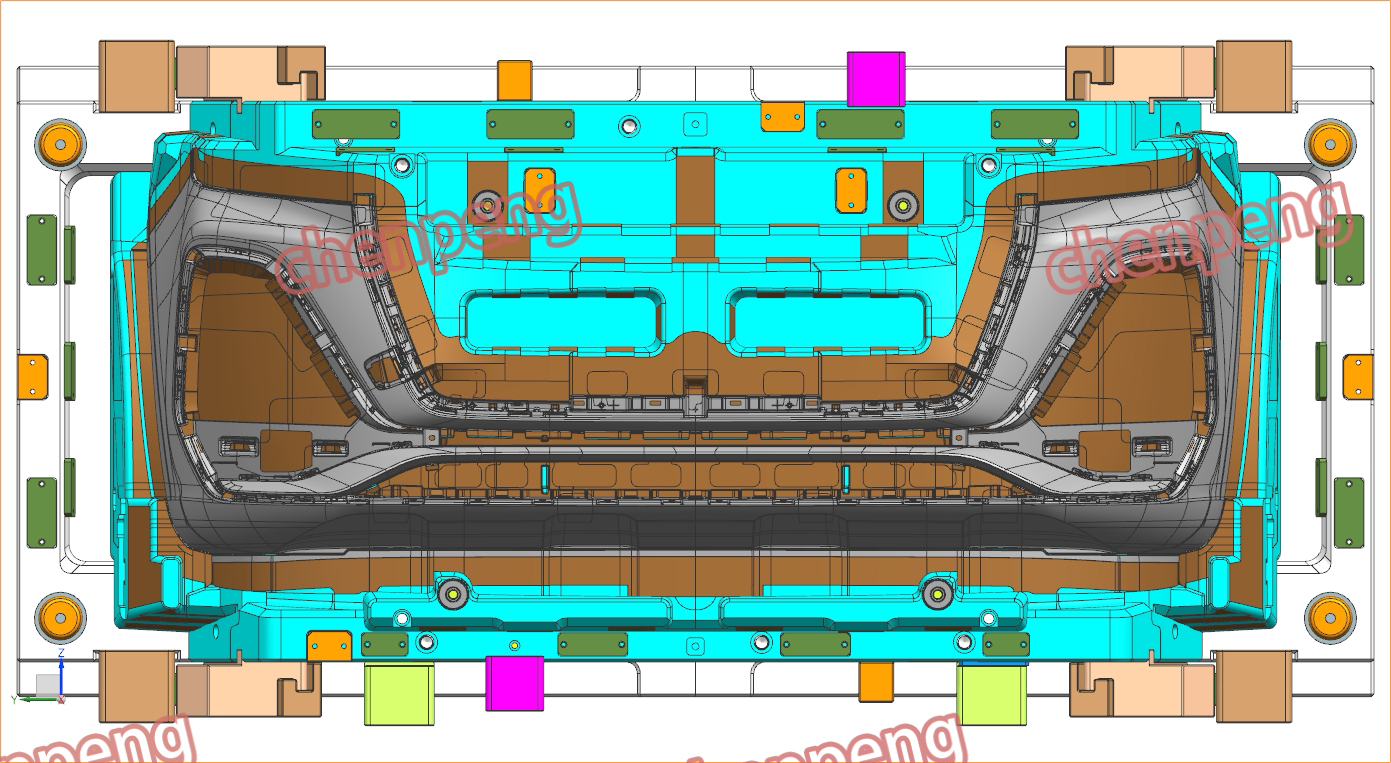

(1) Injection bumper molds

This is the widely used type in the automotive industry. Injection molding can accommodate large bumper dimensions and produce parts with tight tolerances. For example, many popular model vehicles such as midsize sedans and hatchbacks use injection-molded bumpers made from polypropylene-based materials. This method supports rapid mass production and consistent performance.

(2) Blow-molding bumper molds

Blow molding is applied in some lightweight automotive parts but is less frequently used for full bumpers. Some commercial vehicles focus more on impact cushioning and may incorporate blow-molded plastic elements, although the technique is more common for reservoirs and ducts. In bumper manufacturing, it appears in auxiliary protective covers rather than main bumper structures.

(3) Reaction injection molding (RIM) bumper molds

This process involves mixing liquid chemical components, such as polyurethane systems, which react inside the mold. RIM bumpers may appear in vehicles that require improved low-temperature flexibility, such as off-road models. For example, certain pickup trucks adopt RIM techniques to make flexible bumper modules capable of absorbing repeated impact without cracking.

3. Classification by Material Type Used in Molding

Bumper molds are often categorized according to the resin they are meant to process:

(1) PP (Polypropylene) bumper molds

PP is the common material for passenger car bumpers. It has moderate rigidity, good impact resistance, and relatively low weight. Many family sedans and compact cars use PP-based bumper systems. Mold design for this material requires careful control of shrinkage to maintain dimensional stability.

(2) ABS and PC/ABS bumper molds

ABS blends provide better surface quality and scratch resistance. High-end vehicles or models emphasizing exterior aesthetics often choose ABS or PC/ABS, especially for painted bumpers. For example, urban SUVs may require a more refined appearance, making ABS blends suitable.

(3) TPO (Thermoplastic Olefin) bumper molds

TPO bumpers emphasize toughness and elasticity. Some sport utility vehicles and crossovers adopt TPO to withstand frequent minor impacts during off-road or city driving. Molds for TPO need to withstand the material’s higher processing temperatures and shrinkage variations.

(4) Composite material bumper molds

Advanced composite bumpers appear in performance vehicles that value lightweight design. For instance, certain sports cars use composite structures to reduce overall body weight. These molds are often more complex because composite flow behavior must be controlled carefully.

+86-18357617666

+86-18357617666