Injection-Molded Plastic Bumper Molding

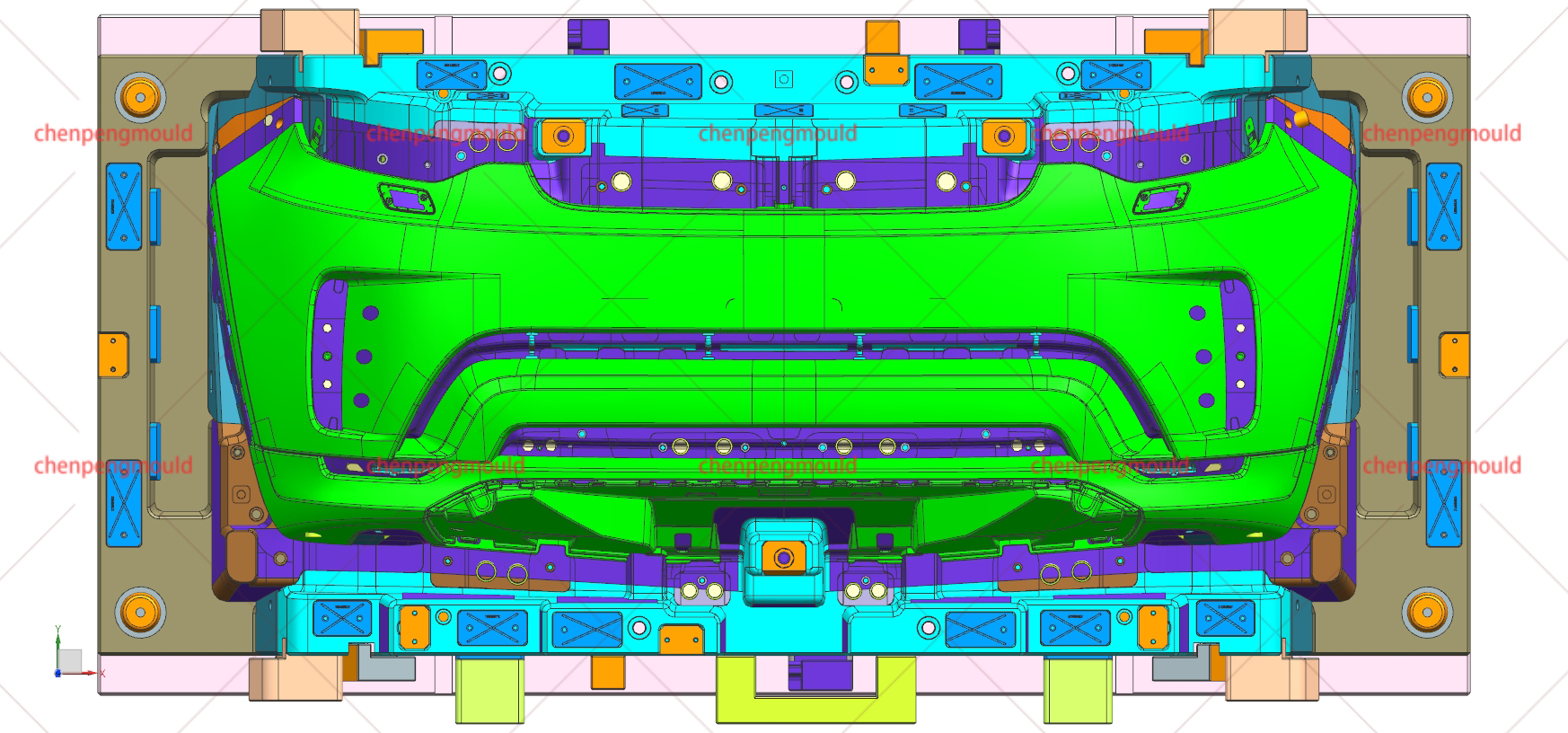

Injection molding is one of the widely used techniques for manufacturing plastic bumper moldings. This process involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. The key advantages of injection-molded plastic bumper moldings are precision, high production efficiency, and the ability to create complex shapes with fine details.

Manufacturing Process: In injection molding, plastic pellets are heated until they become molten. The molten plastic is then injected into a mold under high pressure. Once the plastic has cooled and solidified, the mold is opened to reveal the molded part. This process is highly efficient and suitable for mass production, as the same mold can be used to produce thousands of identical parts.

Applications: Injection-molded plastic bumpers are often used in the production of automotive bumpers that require detailed and intricate designs, such as those with intricate patterns or embossing. This style is particularly well-suited for bumpers that incorporate features such as integrated sensors, lighting, or decorative elements. Because of the precision of the molding process, manufacturers can achieve consistent and high-quality results.

Advantages: Injection molding allows for high levels of customization in terms of the design and shape of the bumper. The ability to produce complex shapes and integrate multiple components into one molded part makes this style highly versatile. Additionally, injection-molded bumpers are cost-effective for large-scale production runs due to the efficiency of the process.

Thermoformed Plastic Bumper Molding

Thermoforming is another common method used to produce plastic bumpers, although it differs from injection molding in terms of the materials and process used. Thermoforming involves heating a plastic sheet until it becomes pliable and then forming it into the desired shape using a mold. This process is particularly suitable for large, flexible bumper moldings with less intricate details.

Manufacturing Process: In thermoforming, a thin sheet of plastic is heated in an oven until it reaches a pliable state. Once the plastic is soft enough, it is stretched over a mold to take on its shape. After cooling, the part is trimmed to remove excess material and ensure a smooth finish. Unlike injection molding, thermoforming is often done using larger sheets of material and may not achieve the fine detail that injection molding can.

Applications: Thermoformed plastic bumpers are often used for larger, simpler designs where intricate detailing is less important. They are ideal for use in bumpers that need to have a uniform shape, such as those for mid-range vehicles or simpler vehicle models. Thermoforming can also be a more cost-effective process for smaller production runs or when bumpers are required in larger sizes.

Advantages: Thermoforming offers several benefits, including faster turnaround times and lower tool costs compared to injection molding. The process also allows for the use of a variety of plastic materials, including those that are more flexible or impact-resistant. Thermoformed bumpers are often lighter in weight, making them suitable for vehicles that prioritize fuel efficiency.

Blow-Molded Plastic Bumper Molding

Blow molding is another manufacturing process used to create plastic bumpers, especially when the bumper requires a hollow or tubular shape. This method is commonly employed when the bumper is designed to have internal cavities or other structural features that need to be lightweight yet strong.

- Manufacturing Process: In blow molding, a heated tube of plastic (called a parison) is extruded into a mold. Once the parison is in the mold, air is blown into it to expand the plastic and form it to the shape of the mold cavity. After the plastic has cooled and solidified, the mold is opened, and the molded part is removed. This process allows manufacturers to create bumpers that have a hollow structure, reducing weight while maintaining strength.

- Applications: Blow-molded bumpers are often used in situations where the bumper needs to have a more complex internal structure, such as when there are requirements for energy absorption during impacts. The ability to create hollow or tubular bumpers makes this process ideal for certain vehicle applications, including larger trucks and SUVs that require bumpers capable of withstanding higher impact forces.

- Advantages: One of the key advantages of blow-molded bumpers is their lightweight nature, which is essential for improving vehicle fuel efficiency. The hollow structure also allows for better energy absorption during collisions, offering enhanced protection to the vehicle and its occupants. Blow molding is particularly effective for producing bumpers that require a specific internal structure or additional reinforcement.

+86-18357617666

+86-18357617666