The automotive industry has seen remarkable advancements over the decades, and one area that exemplifies this progress is the evolution of the bumper mold for cars. From simple designs and basic materials to sophisticated tooling and innovative manufacturing processes, the development of these molds reflects broader trends in automotive engineering and production efficiency.

In the early days of automobile production, bumpers were often made from heavy metal parts, shaped by relatively simple tooling techniques. The bumper mold for cars used in those times was rudimentary, focusing mainly on functionality rather than aesthetics. These early molds lacked the intricate detail and precision machining found in modern equivalents, and the resulting bumpers were often bulky and less refined.

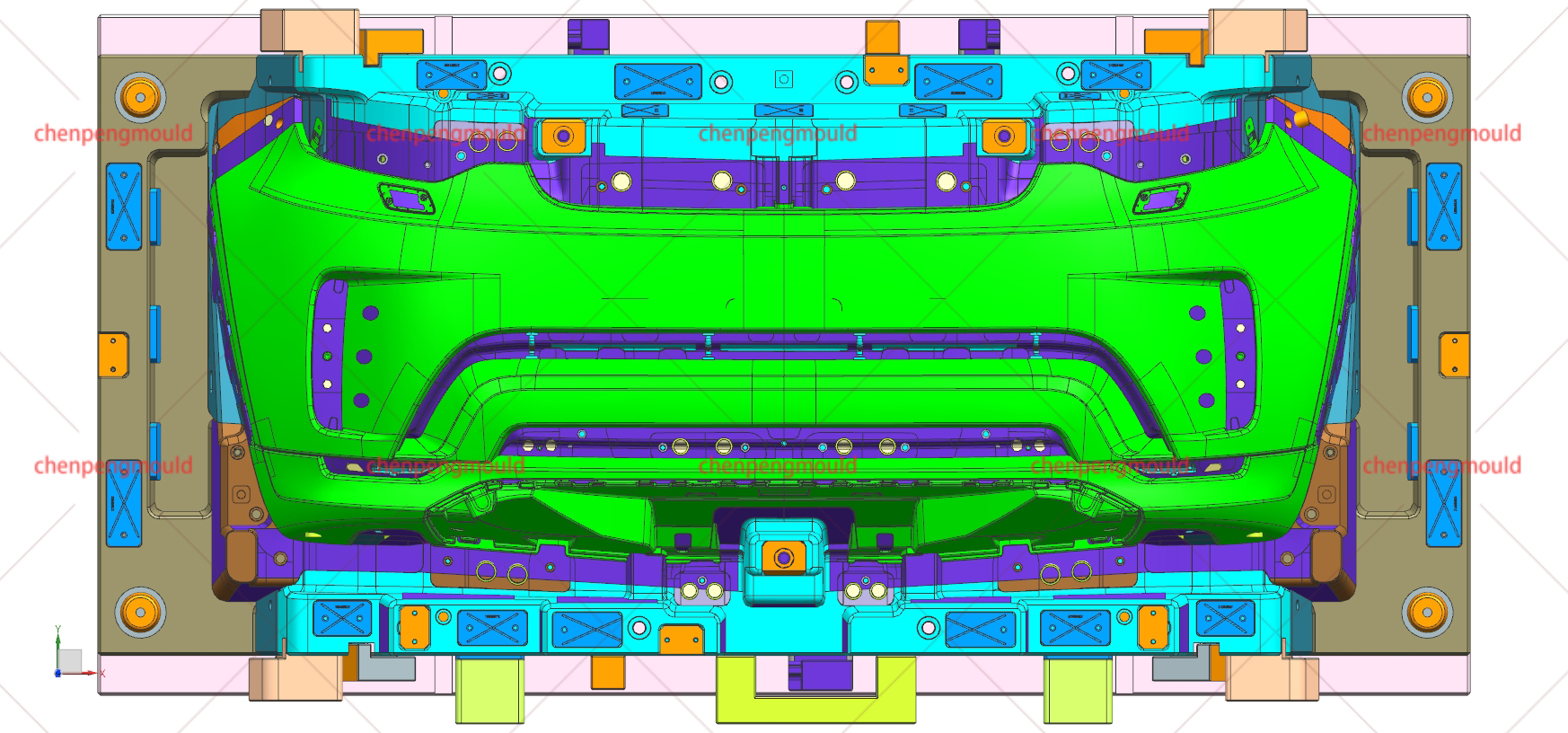

With advancements in materials science, plastic and composite materials began to replace metal for bumper production. This shift required significant changes in mold design and manufacturing. The bumper mold for cars evolved to accommodate injection molding and compression molding processes, which demanded precise control over temperature, pressure, and material flow. Our manufacturing experience shows that creating molds capable of handling these requirements involves careful selection of mold materials, cooling channel design, and surface finishing to ensure consistent quality.

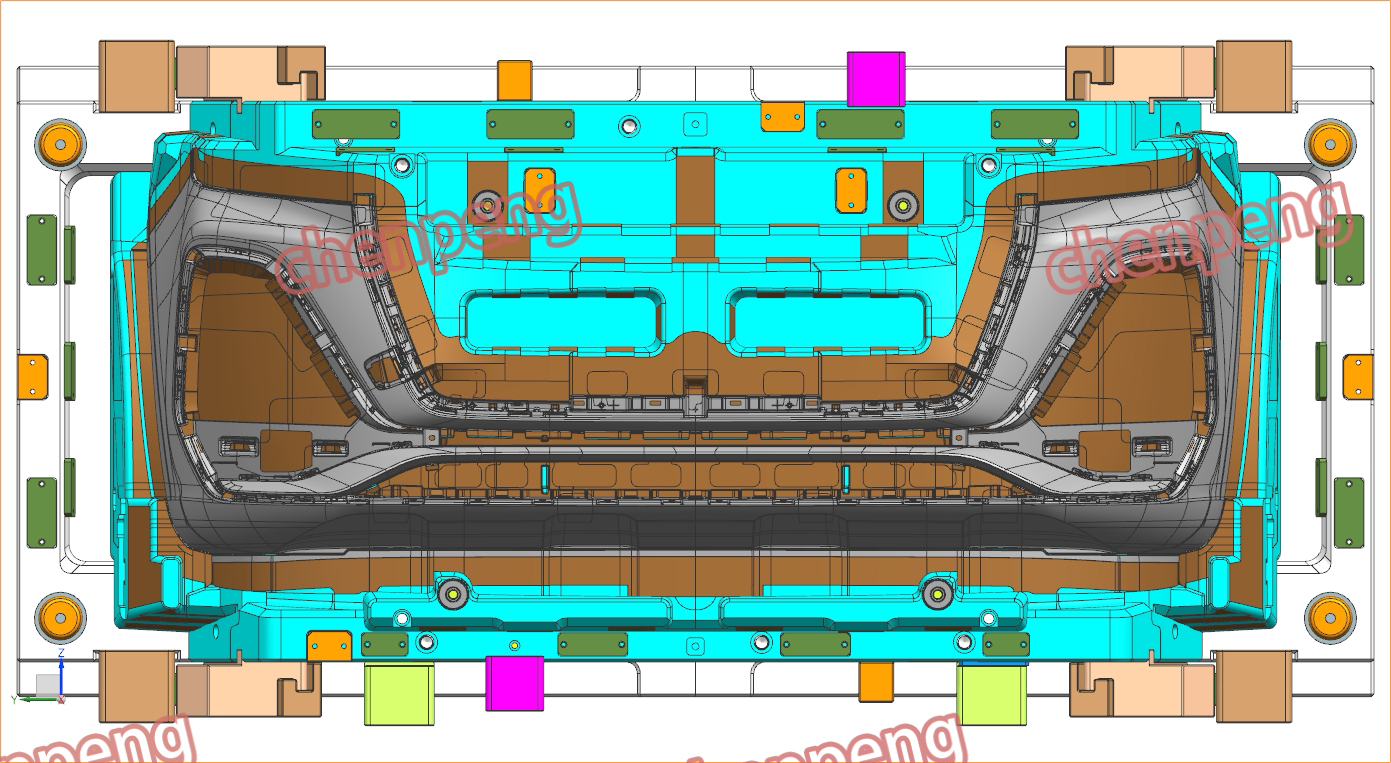

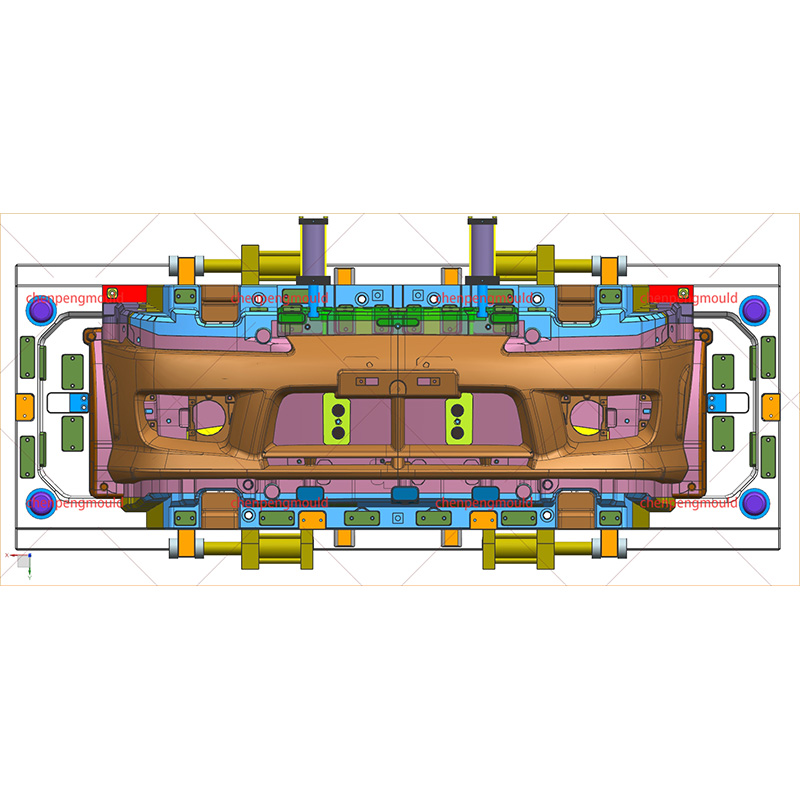

Another key development in the bumper mold for cars is the increased complexity in design. Modern bumpers are no longer simple safety bars; they are integrated parts of the vehicle's aesthetics and aerodynamics. This complexity requires molds that can produce detailed contours, textures, and even embedded functional elements such as sensor mounts. From our perspective, this means investing in advanced CNC machining and polishing techniques to create mold cavities that deliver the desired precision and surface finish.

The scale of production also influences the development of the bumper mold for cars. High-volume manufacturing demands molds that can withstand continuous use without compromising accuracy. To meet these demands, we use hardened steel and other wear-resistant materials, combined with heat treatment processes to extend mold life. Additionally, modular mold designs have become popular, allowing manufacturers to switch out certain sections of the mold to accommodate design changes or different car models, without the need to produce a completely new mold.

Technological advancements have also led to improvements in the efficiency of the molding process itself. Modern bumper mold for cars designs incorporate sophisticated cooling systems to accelerate cycle times and reduce energy consumption. We utilize simulation software during mold development to optimize cooling channel layouts and material flow, resulting in shorter production cycles and improved product consistency.

Automation has played a major role in the development of the bumper mold for cars. Automated systems for material handling, mold clamping, and quality inspection have been integrated into molding lines. These enhancements increase production throughput and reduce human error. As manufacturers, our role extends beyond mold fabrication to providing solutions that integrate seamlessly into automated production environments.

Sustainability considerations have become increasingly important in recent years. The development of the bumper mold for cars now often includes features that reduce material waste and allow for the use of recycled or bio-based plastics. Our manufacturing processes are adapting to these trends by designing molds that minimize scrap and can work with environmentally friendly materials, supporting the automotive industry's goals for greener production.

+86-18357617666

+86-18357617666