The process begins with understanding the original bumper mold's limitations and the intended changes. The modified bumper mold is typically developed to adjust dimensions, strengthen structural areas, or integrate new features, such as sensor mounts or updated grille slots. The goal is to preserve compatibility while enhancing performance or aesthetics.

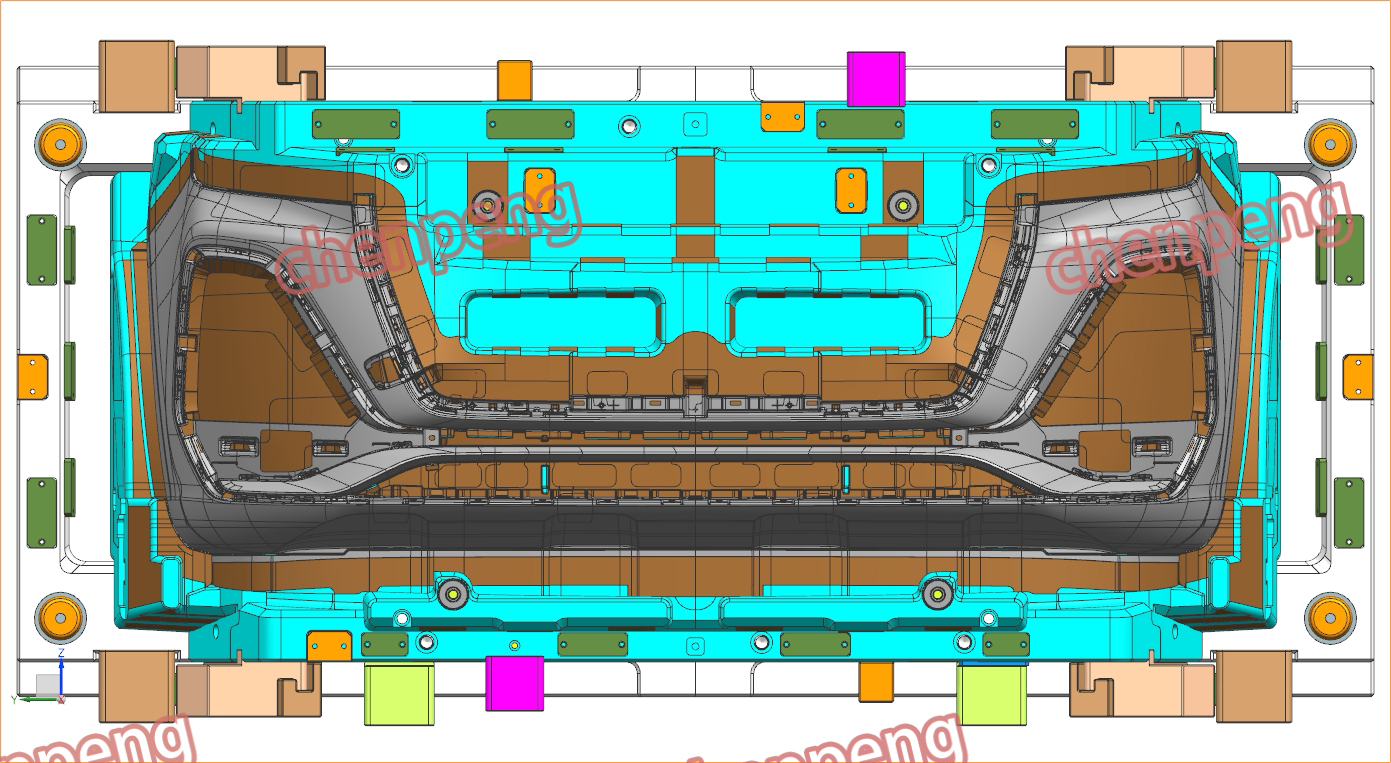

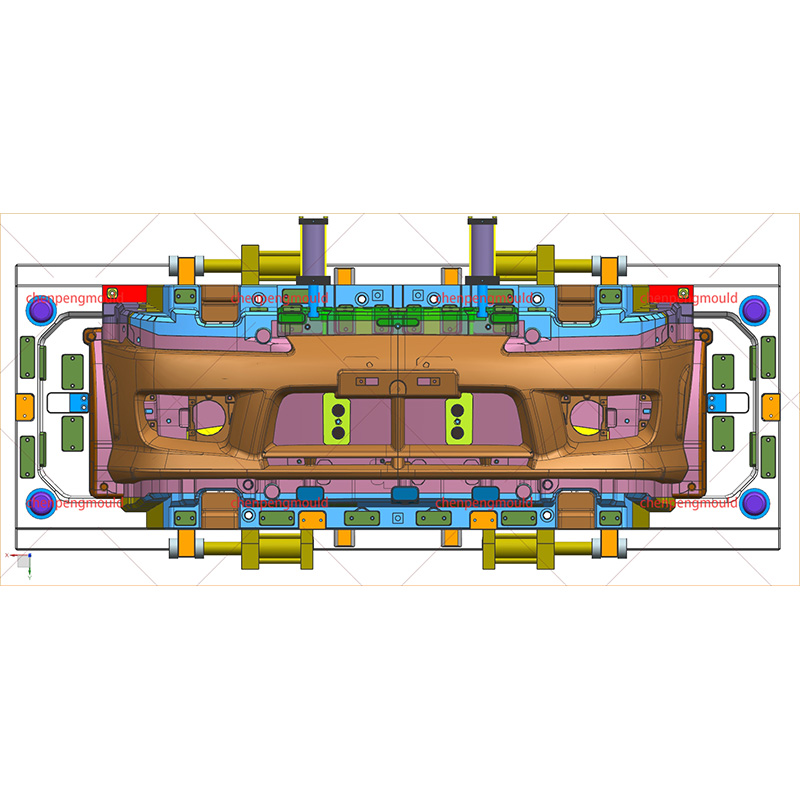

From a manufacturing point of view, creating a modified bumper mold requires CAD redesign, toolpath recalibration, and extensive simulation to ensure flow consistency and material distribution. These adjustments directly affect the finished product's fit and structural properties, which must meet both internal standards and customer specifications.

After the design phase, the modified bumper mold is produced using high-grade tool steel or aluminum alloys, depending on the production volume and complexity. The mold goes through milling, EDM, and surface treatment processes to achieve the required shape and finish.

During molding, thermoplastics such as polypropylene or ABS are injected into the modified bumper mold under controlled temperatures and pressures. This process must be optimized for proper material flow, avoidance of sink marks, and accurate reproduction of the mold's features. The finished bumper emerges from the cavity shaped precisely according to the revised mold, reflecting all modifications.

Dimensional stability is one of the core objectives when using a modified bumper mold. Manufacturers use coordinate measuring machines and digital scanners to verify that the finished product matches the intended geometry. Every curve, cutout, and mounting point must align with downstream assembly requirements.

Accuracy is further ensured through mold trial runs, during which the modified bumper mold is evaluated for shrinkage, warpage, and cooling performance. Adjustments are made to the tooling or process parameters before starting mass production. The aim is to eliminate deviation across batches, resulting in uniform finished products.

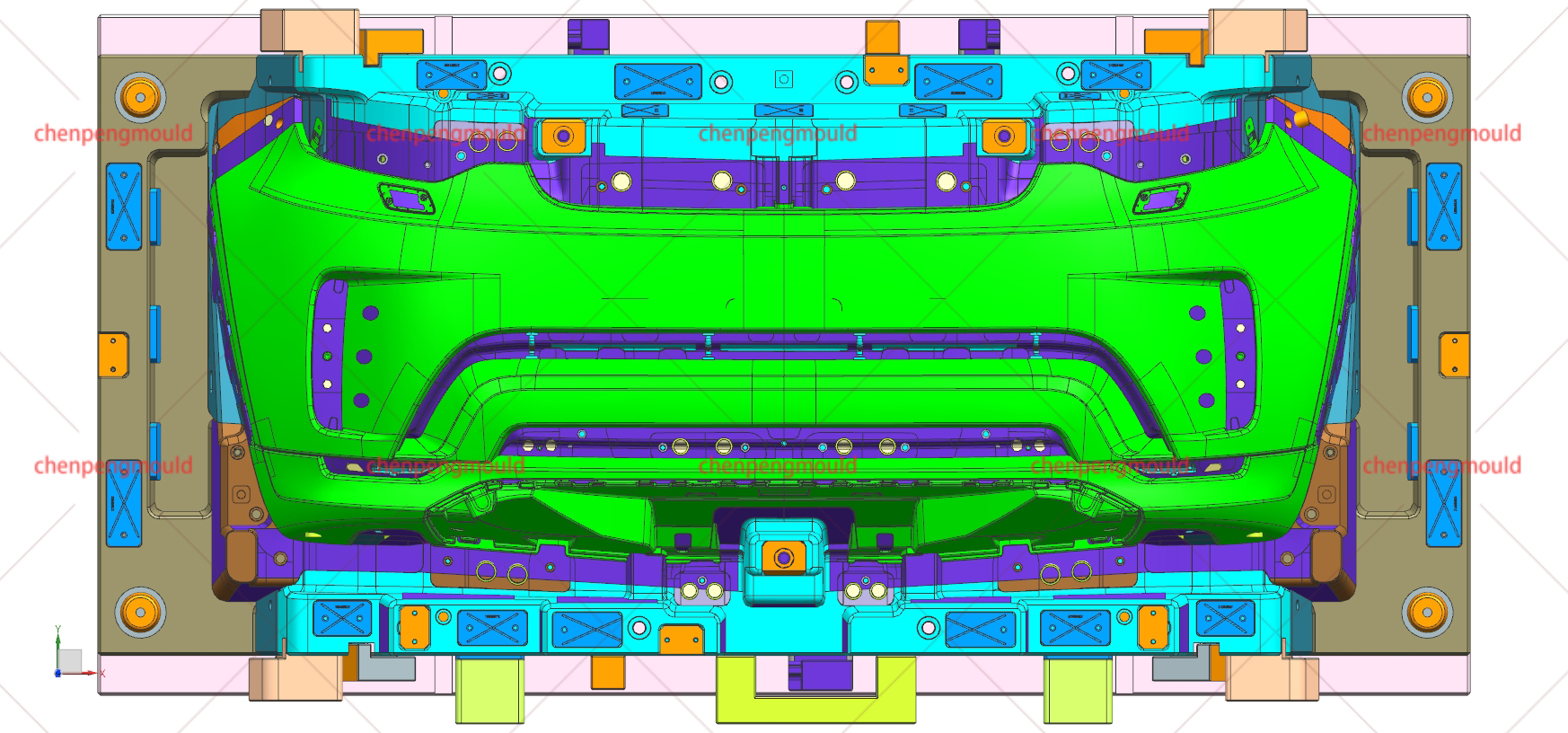

The final surface condition of a bumper produced from a modified bumper mold must meet both visual and functional criteria. Manufacturers apply various mold surface treatments—such as polishing, texturing, or chemical etching—depending on the design intent. These treatments are directly imprinted onto the finished bumper, ensuring consistency without additional post-processing.

If a glossy or matte texture is specified, the mold surface is prepared accordingly to replicate that finish. The modified bumper mold must be maintained meticulously to preserve this quality across long production runs. Any wear or imperfection in the mold surface can reflect on the finished product, necessitating repairs or refurbishments.

Once ejected from the modified bumper mold, the part is trimmed and inspected before entering the vehicle assembly line. The critical assessment at this stage is how well the bumper integrates with adjacent components such as fenders, headlamps, and mounting brackets.

The manufacturer's goal is to produce a finished bumper that aligns correctly without requiring excessive manual adjustment. This compatibility depends entirely on how precisely the modified bumper mold has been engineered and how stable the molding process remains under production conditions.

Achieving a high-quality finished product from a modified bumper mold involves several challenges. These include managing cooling rates to avoid distortion, compensating for material shrinkage, and ensuring repeatable mold function. In high-output environments, cycle time optimization must be balanced with maintaining product integrity.

Each of these challenges must be addressed during both the mold modification and testing phases. Manufacturers often use simulation software to predict outcomes before physical trials begin. The effectiveness of the modified bumper mold is judged by how little rework or scrap it generates during production.

+86-18357617666

+86-18357617666