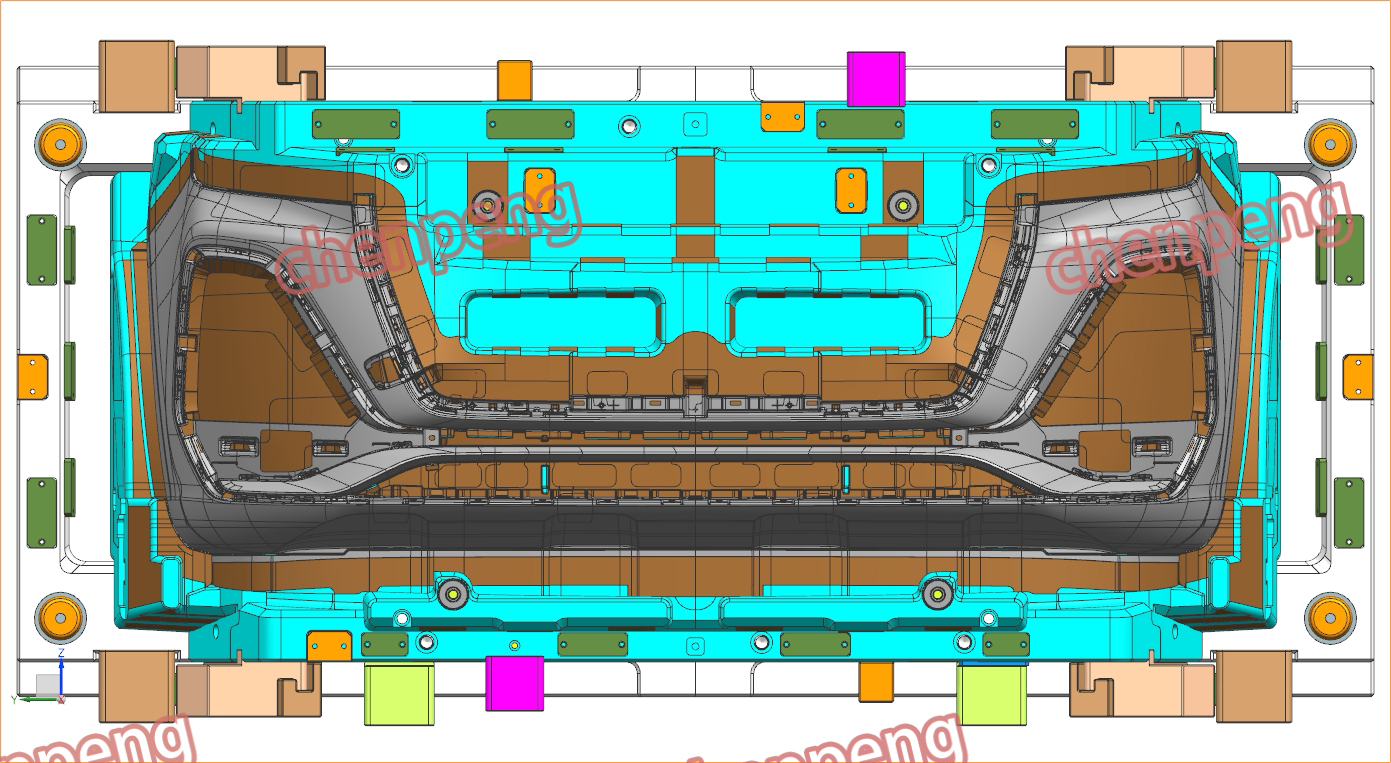

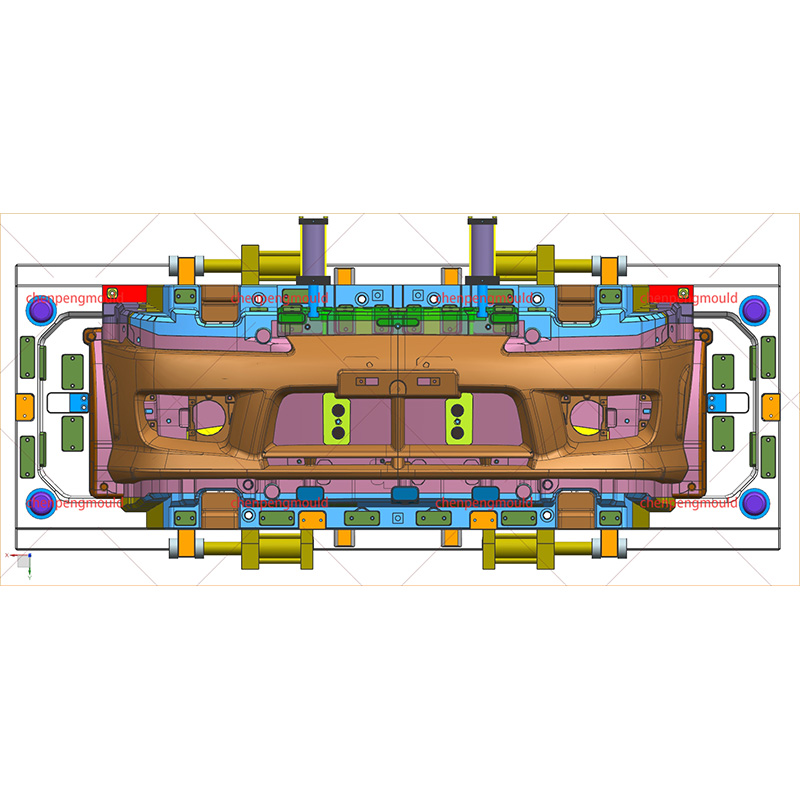

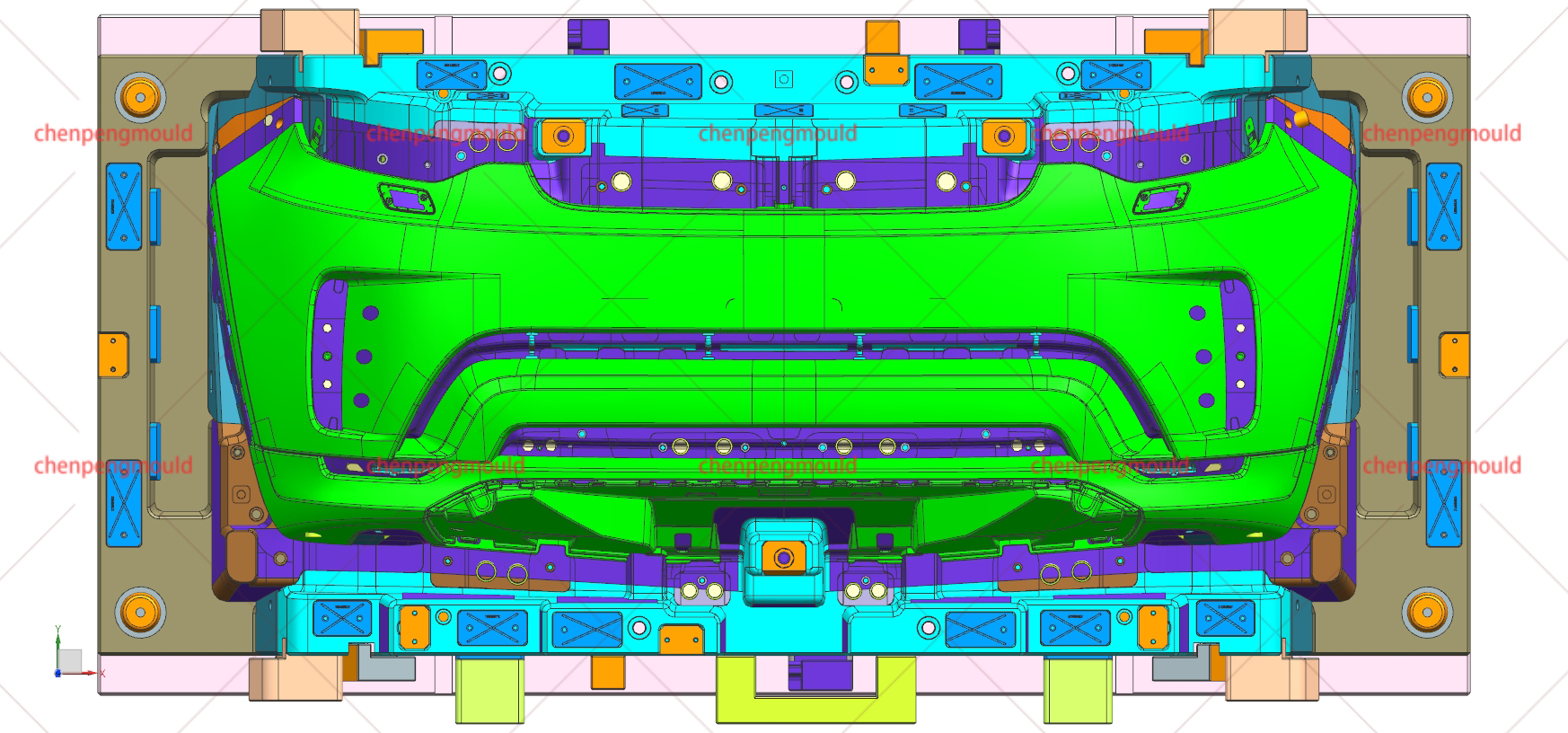

At its core, the car bumper mold is a tool used to shape and form the bumper components during the manufacturing process. These molds are typically constructed from high-strength materials such as steel or aluminum, designed to withstand the pressures and temperatures involved in molding processes. The car bumper mold creates the exact shape, size, and surface finish required for the bumper, ensuring each unit produced is consistent.

One of the primary functions of the car bumper mold is to provide precision. The mold's cavity is engineered based on detailed designs that take into account the vehicle's make and model specifications. This ensures that the bumper fits on the vehicle's frame and aligns with other body parts. From our manufacturing experience, the accuracy of the mold directly influences the final quality of the bumper, the need for post-processing adjustments.

Durability is another important function. The car bumper mold must endure repeated use without deformation or loss of accuracy. Because the molding process often involves high temperatures and pressures, the mold is designed to maintain its integrity under these conditions. We employ advanced machining and heat treatment techniques to enhance the strength and longevity of the mold, which helps reduce downtime and replacement costs.

The car bumper mold also plays a role in determining the surface quality of the bumper. The internal surfaces of the mold are carefully finished to ensure the molded bumper has a smooth and defect-free exterior. This finishing process is crucial because it impacts the paint adhesion and overall appearance of the bumper. As manufacturers, we pay close attention to polishing and surface treatment methods to maintain high standards.

Production efficiency is closely tied to the design of the car bumper mold. A well-designed mold allows for quick cycle times during the molding process, enabling manufacturers to meet high-volume demands. Features such as cooling channels and ejector systems integrated into the mold help speed up the cooling and removal of the bumper from the mold cavity, improving throughput without sacrificing quality.

Flexibility in design is also a function of modern car bumper molds. Manufacturers often need to accommodate design updates or variations for different car models. Modular mold designs allow for adjustments without the need to produce entirely new molds. This adaptability is a significant advantage in the automotive industry, where designs can change frequently.

From a safety perspective, the car bumper mold must ensure that the molded bumper meets impact resistance requirements. The mold's design affects the wall thickness and structural integrity of the bumper, which are critical factors in protecting vehicle occupants during collisions. We collaborate closely with material suppliers and engineers to ensure that the mold supports the use of materials that provide strength and flexibility.

Cost control is another aspect linked to the car bumper mold. Although initial mold development requires investment, the durability and efficiency of the mold reduce overall production costs. A robust mold minimizes defects and waste, fewer rejected parts and less rework. This economic efficiency is a core consideration in our manufacturing process.

Quality control is deeply connected with the use of the car bumper mold. Each mold undergoes thorough testing and validation to ensure it meets dimensional and performance specifications. We perform trial runs and make necessary adjustments to the mold to achieve the desired output quality. This step is vital to maintain consistency throughout the production lifecycle.

In addition, the car bumper mold influences environmental impact. Efficient mold design reduces material waste and energy consumption during production. We focus on incorporating sustainable manufacturing practices by optimizing mold cooling systems and using environmentally friendly materials in mold construction.

+86-18357617666

+86-18357617666